In the world of bulk material handling, conveyor belt systems are the workhorses of industries like mining, aggregate, cement, power generation, and logistics. A critical component of these systems is the primary belt cleaner, or scraper, installed at the head pulley to remove material carryback. While various materials are used for scraper blades, tungsten carbide has emerged as the superior choice, offering significant long term benefits that translate directly to improved operational efficiency, reduced costs, and enhanced safety.

1. Exceptional Wear Resistance and Extended Service Life

This is the most significant long term benefit. Tungsten carbide is one of the hardest materials available for industrial applications, second only to diamond.

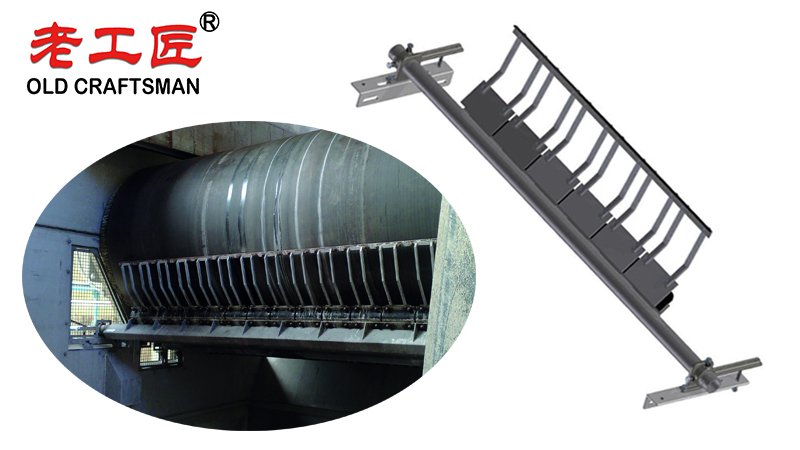

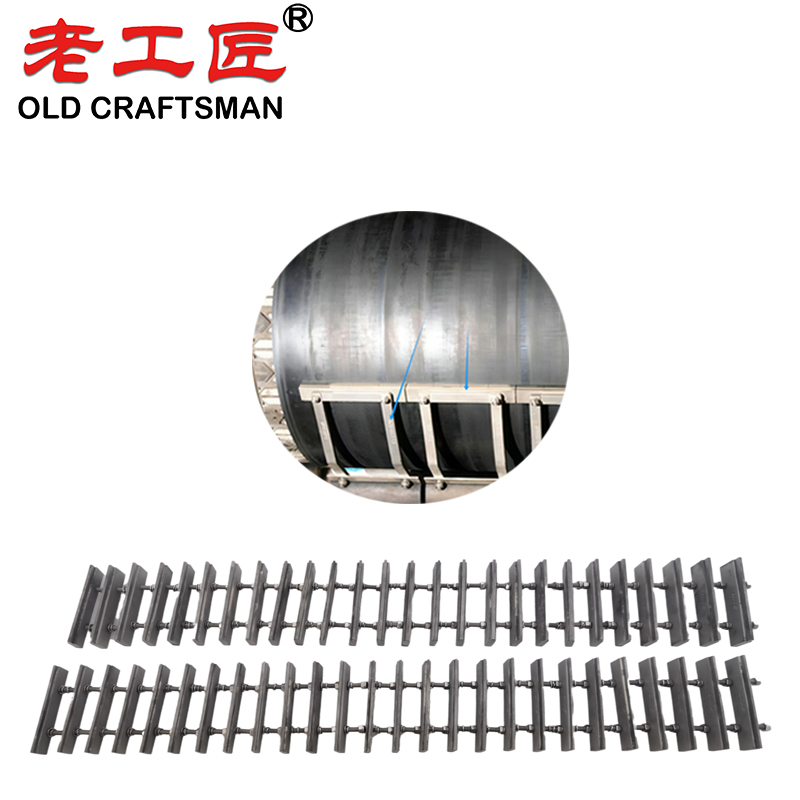

- Mechanism: Unlike polyurethane or steel blades that wear down through abrasion, tungsten carbide scrapers typically utilize a unique “wear-to-fit” design with multiple, independently rotating carbide tiles or a segmented strip. As the blade wears, fresh, sharp carbide edges are continuously presented to the belt.

- Long-Term Impact: This results in a service life that is 5 to 10 times longer than conventional polyurethane blades and significantly longer than steel. This means:

- Fewer Changeouts: Maintenance teams spend less time and labor on replacing scraper blades.

- Reduced Inventory: Facilities need to stock far fewer replacement blades, lowering inventory carrying costs.

- Consistent Performance: The blade maintains optimal cleaning efficiency throughout its entire lifespan, without a rapid performance drop-off.

2. Superior Cleaning Performance and Reduced Carryback

Carryback—the material that fails to discharge and sticks to the belt is the primary source of numerous operational problems.

- Mechanism: The extreme hardness of tungsten carbide allows it to maintain a sharp, precise cleaning edge against the belt contour. It effectively scrapes off even the most stubborn, sticky materials without deflecting or degrading.

- Long-Term Impact:

- Cleaner Operation: Drastically reduced carryback means less material accumulation under the conveyor, on rollers, and along the return path. This creates a fundamentally cleaner plant environment.

- Lower Housekeeping Costs: The need for manual cleaning with shovels, pressure washers, and vacuum trucks is minimized, leading to substantial savings in labor, water, and equipment maintenance.

- Improved Safety: Reduced material spillage eliminates slip-and-fall hazards and minimizes dust generation, a critical factor for worker health and safety.

3. Protection of the Conveyor Belt Itself

A worn or improperly tensioned scraper can cause severe belt wear. Tungsten carbide, when correctly installed and tensioned, is surprisingly gentle on the belt.

- Mechanism: The key is the blade’s design. The rotating carbide tiles or segments are designed to clean with minimal pressure. They “wipe” rather than “scrape,” reducing friction and heat buildup.

- Long-Term Impact:

- Extended Belt Life: By preventing gouging and excessive wear of the belt’s top cover, the conveyor belt itself lasts significantly longer. Given that a conveyor belt is one of the most expensive assets in the system, this protection offers an enormous return on investment.

- Prevention of Costly Damage: It avoids catastrophic belt damage that could lead to unplanned downtime and expensive emergency repairs.

4. Reduced Downtime and Maintenance Costs

The combination of extended service life, consistent performance, and belt protection leads to a dramatic reduction in overall maintenance requirements.

- Long-Term Impact:

- Planned vs. Unplanned Maintenance: Replacements become predictable, planned events rather than emergency reactions to a failed cleaner or a damaged belt.

- Lower Total Cost of Ownership (TCO): While the initial purchase price of a tungsten carbide scraper system is higher than alternatives, the long term savings on replacement blades, labor, housekeeping, and belt replacement result in a significantly lower TCO over the lifespan of the conveyor.

5. Energy Efficiency

This is an often overlooked benefit. A clean belt runs more efficiently.

- Mechanism: Carryback accumulating on rollers and idlers increases the mechanical resistance the conveyor drive must overcome. A heavier, misaligned return belt also requires more energy to move.

- Long Term Impact: By keeping the belt and structure clean, the conveyor system operates with less strain, potentially reducing energy consumption and lowering electricity costs over thousands of operating hours.

Summary of Long-Term Benefits

| Benefit | Short-Term Effect | Long-Term Impact |

|---|---|---|

| Exceptional Wear Life | Higher initial cost | Massive reduction in replacement part costs and labor. |

| Superior Cleaning | Less immediate carryback | Dramatically lower housekeeping costs, improved safety, less dust. |

| Belt Protection | Gentle cleaning action | Extended belt life, avoidance of catastrophic belt damage. |

| Reduced Downtime | Reliable performance | Maintenance becomes planned and predictable, increasing system availability. |

| Energy Efficiency | Cleaner system operation | Lower power consumption and reduced strain on drives. |

Important Consideration: Proper Installation is Key

To fully realize these long term benefits, correct installation and tensioning are non-negotiable. Tungsten carbide is unforgiving if installed incorrectly. Excessive tension can lead to premature belt wear, while insufficient tension will cause poor cleaning. It is crucial to follow the manufacturer’s guidelines precisely, often involving the use of a tension gauge to achieve the perfect balance.

In bulk material handling facilities, heavy duty belt conveyors and roller conveyors form the backbone of efficient material flow, transporting material across assembly lines and processing plants with increased productivity. To ensure these systems work reliably over the long term and operate efficiently, proper belt tracking and effective mining conveyor belt scraper systems are essential, as they remove carryback and reduce wear and tear on the belt system. Belt slippage, misalignment, and excessive buildup can quickly lead to costly downtime, making preventative maintenance and regular inspections critical for optimal performance. By investing in high quality scrapers and maintaining all types of conveyor systems cost effectively, operators can minimize unexpected failures, extend equipment life, and keep production running smoothly.

Conclusion

Investing in a high quality tungsten carbide scraper system is a strategic decision focused on long term operational excellence. It moves the focus from reactive, costly maintenance to proactive, efficient system management. The significant savings in parts, labor, housekeeping, and energy, combined with the extended life of the conveyor belt itself, ensure that a tungsten carbide scraper provides an outstanding return on investment and is a cornerstone of any modern, efficient bulk material handling operation.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding