1. High Manganese Steel

- Performance Characteristics:

- High Toughness and Wear Resistance: High manganese steel (e.g., Mn13 or Mn18) is known for its excellent toughness and work-hardening ability. When subjected to impact or pressure, its surface hardness increases significantly, enhancing wear resistance.

- Impact Resistance: It excels in handling high-impact conditions, making it suitable for crushing hard and abrasive materials like granite or basalt.

- Limitations: Its initial hardness is relatively low, so it performs poorly under low-impact or non-abrasive conditions, as the work-hardening effect is not fully triggered.

- Applications: Widely used in mining, quarrying, and recycling industries for crushing tough, abrasive materials.

2. High Chromium Cast Iron2. High Chromium Cast Iron

- Performance Characteristics:

- High Hardness and Wear Resistance: High chromium cast iron (e.g., Cr20 or Cr26) has a high initial hardness due to the presence of chromium carbides, offering superior wear resistance, especially against abrasive materials.

- Corrosion Resistance: The chromium content provides good resistance to oxidation and corrosion, extending the hammerhead’s lifespan in harsh environments.

- Limitations: It has lower toughness and is brittle, making it prone to cracking under high-impact conditions.

- Applications: Ideal for crushing medium-hard, highly abrasive materials such as limestone, coal, and clinker in cement production.

3. Alloy Steel

- Performance Characteristics:

- Balanced Properties: Alloy steel hammerheads (e.g., containing elements like chromium, molybdenum, or nickel) offer a balance between hardness and toughness, depending on the specific alloy composition.

- Customizability: The material can be tailored to specific needs by adjusting the alloying elements, improving wear resistance, impact resistance, or thermal stability.

- Limitations: Generally less wear-resistant than high chromium cast iron and less tough than high manganese steel in extreme conditions.

- Applications: Suitable for a wide range of materials, including medium-hard rocks and ores, where versatility is required.

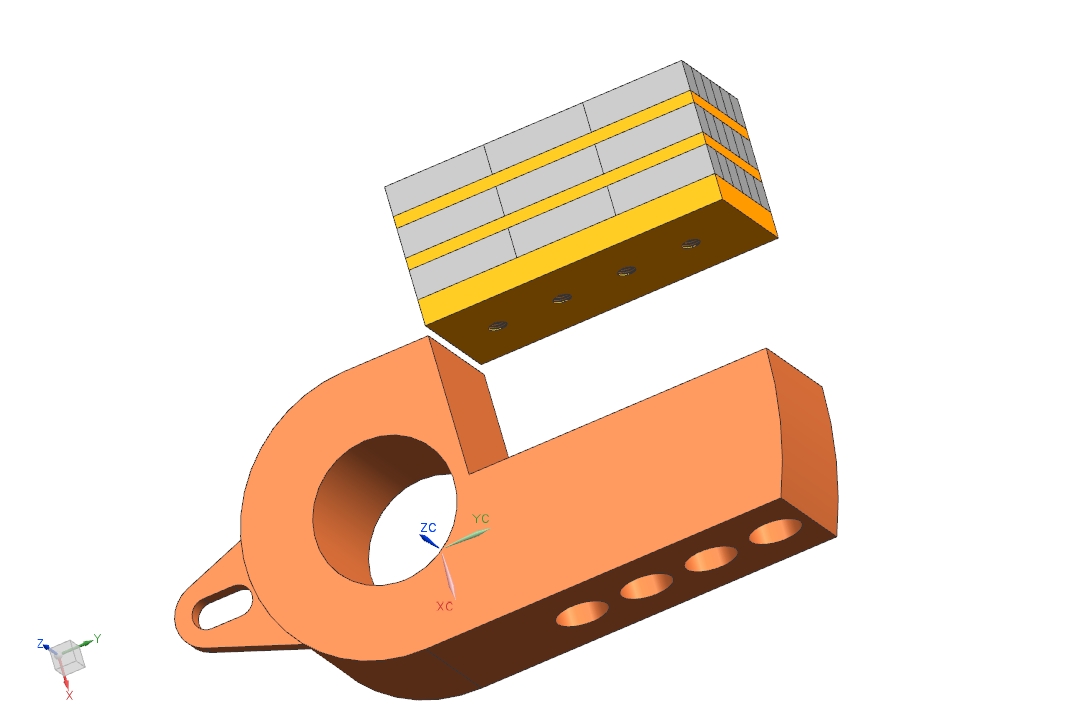

4. Bimetallic Composite Materials

- Performance Characteristics:

- Dual Properties: These hammerheads combine two materials (e.g., high chromium cast iron for the head and high manganese steel for the shank). The wear-resistant part handles abrasion, while the tougher part absorbs impact.

- Long Service Life: The combination enhances overall durability and reduces replacement frequency.

- Limitations: Manufacturing complexity increases costs, and improper bonding between materials can lead to failure.

- Applications: Used in demanding environments like mining and cement industries, where both high wear and impact resistance are needed.

5. Tungsten Carbide

- Performance Characteristics:

- Exceptional Hardness: Tungsten carbide hammerheads offer unmatched hardness and wear resistance, far exceeding traditional materials.

- Abrasion Resistance: Ideal for extremely abrasive materials, maintaining performance over extended periods.

- Limitations: Very brittle and expensive, with poor resistance to high-impact forces, limiting its use in heavy-duty crushing.

- Applications: Typically used as inserts or overlays in hammerheads for specialized tasks, such as crushing highly abrasive ores or in fine crushing processes.

Comparison Summary

| Material | Hardness | Toughness | Wear Resistance | Impact Resistance | Cost | Best Use Case |

| High Manganese Steel | Medium | High | High (after hardening) | Excellent | Moderate | Hard, abrasive materials |

| High Chromium Cast Iron | High | Low | Excellent | Poor | Moderate | Medium-hard, abrasive materials |

| Alloy Steel | Medium | Medium | Good | Good | Moderate | Versatile applications |

| Bimetallic Composite | High | High | Excellent | Excellent | High | High-impact, abrasive tasks |

| Tungsten Carbide | Very High | Medium | Exceptional | Medium | High | Extreme abrasion, low impact |

Conclusion

The choice of material for crusher hammerheads depends on the specific crushing task:

- For high-impact, tough materials, high manganese steel or bimetallic composites are optimal.

- For highly abrasive, medium-hard materials, high chromium cast iron or tungsten carbide (as inserts) performs best.

- For general-purpose crushing, alloy steel provides a cost-effective, balanced solution.

Crusher carbide hammers are manufactured from high-quality carbon steel or specially developed alloy steels that incorporate strategic alloying elements such as chromium, molybdenum, tungsten, and vanadium to provide a wide range of superior mechanical properties. Through precisely controlled heat treatment processes (typically involving quenching and multiple tempering stages), these materials achieve exceptional hardness (often 55–65 HRC), high wear resistance, and the unique property of combining extreme toughness with the ability to absorb energy under heavy impact loads. At room temperature, the base carbon steel matrix provides good ductility, while the dispersed carbide phases make the hammer tips highly resistant to abrasive wear. At high temperature conditions encountered during intensive crushing operations, the carefully selected alloying elements ensure retained hardness and the ability to resist softening and thermal fatigue. Common types of materials include conventional heat treated high-chrome white irons and advanced tungsten-carbide-reinforced composites or metal-matrix composites with reinforced plastics in some hybrid designs. These properties make crusher carbide hammers the preferred choice for demanding industrial applications such as mining, quarrying, cement production, and recycling, where their outstanding impact and abrasion resistance significantly extends service life, reduces long-term maintenance costs, and justifies the initial material selection premium compared to standard manganese or carbon steel alternatives.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide crusher hammer and make your crusher hammer use life is tens of times longer than before! We specialize in providing customized carbide solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding