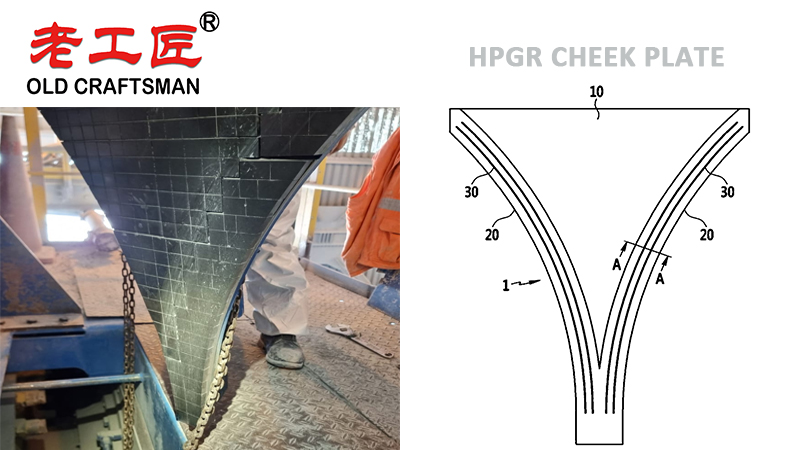

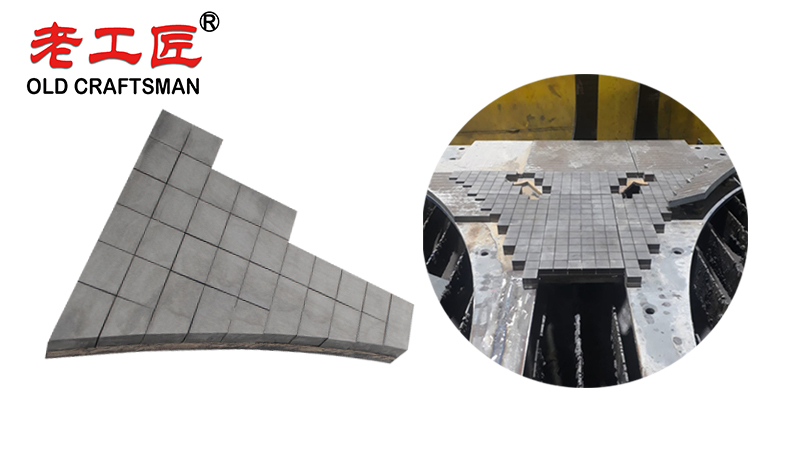

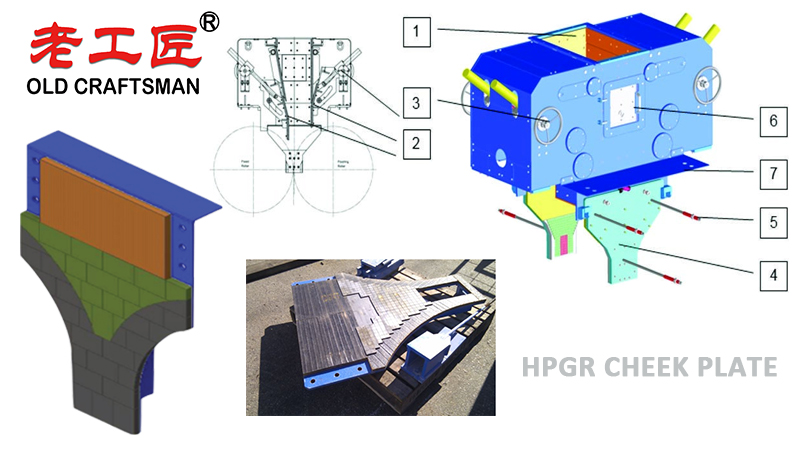

High Pressure grinding rolls (HPGRs) are critical in modern ore processing, offering energy efficient comminution. Tungsten carbide (WC) cheek plates are essential components in HPGRs due to their extreme wear resistance, toughness, and durability under high compressive forces. Here’s the science behind their effectiveness:

1. Why Tungsten Carbide in HPGRs?

HPGRs operate under extremely high pressures (50–300 MPa), generating intense interparticle crushing and microcracking of ores. This creates severe abrasive and impact wear on cheek plates. WC’s unique properties make it ideal for this application:

Key Properties of WC for HPGR Cheek Plates

| Property | Tungsten Carbide (WC-Co) | Manganese Steel | Ceramics (e.g., Al₂O₃) |

|---|---|---|---|

| Hardness (HV) | 1,500–2,500 | 200–600 | 1,500–2,000 |

| Compressive Strength | ~6,000 MPa | ~2,500 MPa | ~3,500 MPa |

| Fracture Toughness (K<sub>IC</sub>) | 10–15 MPa·m<sup>1/2</sup> | High (~100+) | Low (~3–5) |

| Wear Resistance | Excellent | Moderate | High (but brittle) |

| Thermal Stability | Stable up to 600°C | Softens at high temps | Stable but brittle |

2. Material Science Behind WC Cheek Plates

(a) Microstructure & Composition

- WC grains (85–94%): Provide extreme hardness and wear resistance.

- Cobalt binder (6–15%): Adds toughness by preventing crack propagation.

- Grain size optimization:

- Fine grains (0.5–1 µm): Higher hardness, better wear resistance.

- Coarse grains (2–5 µm): Better toughness, crack resistance.

(b) Wear Mechanisms in HPGRs

- Abrasive Wear (dominant) – Hard ore particles (e.g., quartz, iron oxides) gouge the surface.

- WC’s extreme hardness minimizes material loss.

- Impact Wear – Repeated compression cycles cause micro-fracturing.

- Cobalt binder absorbs energy, preventing catastrophic failure.

- Fatigue Wear – Cyclic loading leads to crack propagation.

- WC-Co’s high compressive strength resists fatigue.

(c) Thermal & Chemical Stability

- Low thermal expansion prevents warping under frictional heating.

- Chemical inertness resists oxidation and corrosion from wet ores.

3. Design & Manufacturing Considerations

(a) Optimized WC Grades for HPGRs

| Grade | Binder % | Grain Size | Best For |

|---|---|---|---|

| Ultra-fine | 6–9% Co | 0.5–1 µm | Highly abrasive ores (iron, gold) |

| Medium-coarse | 10–12% Co | 1–3 µm | Balanced wear/toughness (copper, nickel) |

| High-toughness | 12–15% Co | 3–5 µm | High-impact ores (diamonds, PGM) |

(b) Surface Engineering

- Functionally graded WC: Harder surface layer with a tougher core.

- Protective coatings (e.g., diamond-like carbon, DLC) further reduce wear.

4. Performance vs. Alternatives

| Material | Wear Life (vs. WC) | Maintenance Cost | Best For |

|---|---|---|---|

| Tungsten Carbide | 5–10x longer | High initial cost, low replacement | Hard, abrasive ores |

| Manganese Steel | 1x (baseline) | Low initial cost, frequent replacement | Low abrasion ores |

| Ceramics (Al₂O₃, ZrO₂) | 3–5x longer | Moderate cost, brittle failure risk | Non-impact grinding |

5. Future Trends

- Nano-structured WC: Improved hardness & toughness.

- Binderless WC: Eliminates Co for extreme wear resistance.

- Additive manufacturing (3D printing): Custom cheek plate geometries for optimized wear.

The material properties of tungsten carbide cheek plates used in High Pressure Grinding Rolls (HPGR) are critical to achieving extended service life under extreme operating conditions. These wear parts, typically made from cobalt-bonded WC grades, exhibit exceptionally high compressive strength, moderate tensile strength (usually 300–600 MPa), and excellent plane strain fracture toughness (K_IC typically 10–20 MPa·m¹/²), as determined by linear elastic fracture mechanics (LEFM) and standard test methods such as ASTM E399. Stress-strain curves under compression show minimal plastic deformation before failure, while the applied load during operation can exceed 100–150 N/mm², generating intense three-body abrasive wear, adhesive wear, and surface fatigue on the cutting edges and cheek plate surfaces. Wear occurs primarily through micro-chipping, binder extrusion, and fatigue crack growth (often characterized by Paris-law parameters in da/dN vs ΔK plots), exacerbated at high temperatures (>400 °C) due to cobalt binder softening and oxidation. To evaluate performance, standardized laboratory test methods including ASTM G65 dry sand/rubber wheel abrasion, pin-on-disk at elevated temperature, and modified high-stress abrasion tests are commonly employed. Proper material selection, balancing hardness (typically 85–92 HRA), fracture toughness, and thermal stability, is essential to resist the combined effects of high blood pressure like compressive stresses, cyclic loading, and abrasive mineral environments, ultimately maximizing cheek plate durability and HPGR uptime.

Conclusion

Tungsten carbide cheek plates in HPGRs excel due to their optimal balance of hardness, toughness, and thermal stability, making them indispensable for processing hard and abrasive ores. While costly upfront, their extended lifespan and reduced downtime justify the investment in high throughput mining operations.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding