Custom tungsten carbide edge blocks represent a paradigm shift in HPGR wear protection. Moving beyond traditional welded hardfacing or homogeneous alloy tires, this solution involves mechanically fastened, custom engineered blocks of tungsten carbide composite. They offer a dramatic increase in wear life, improved energy efficiency, and enhanced operational consistency, establishing a new benchmark for cost effectiveness in comminution.

The Problem: Why HPGRs are So Hard on Wear Parts

HPGRs operate by applying extreme pressure (e.g., 50-600 MPa) to a bed of ore, causing inter-particle crushing. This environment is brutally abrasive for the roll surfaces. Traditional solutions have significant drawbacks:

- Welded Hardfacing: Applied manually or automatically, these welds wear unevenly, leading to a loss of the optimal “cheek” profile. This reduces efficiency and requires frequent, costly re-applications with significant downtime.

- Homogeneous Alloy Rolls: While tougher, these solid alloy rolls wear down over time, changing the roll gap and product size distribution. They eventually require expensive rebuilding or replacement.

- Uniform Wear: Both methods lead to profile loss, which compromises the “edge seal” against the cheek plates, causing side leakage of feed material and reducing the effective pressure in the grinding zone.

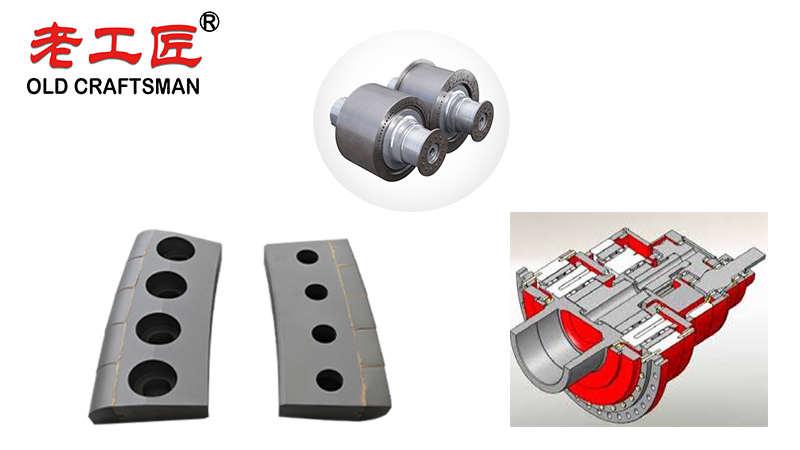

The Solution: Custom Tungsten Carbide Edge Blocks

This solution addresses these shortcomings by placing the most wear resistant material precisely where it’s needed most the roll edges and high wear areas.

What Are They?

- Material: A composite material consisting of tungsten carbide (WC) grains embedded in a tough, metallic binder matrix (typically cobalt or nickel). This combination provides extreme hardness from the carbides and fracture resistance from the binder.

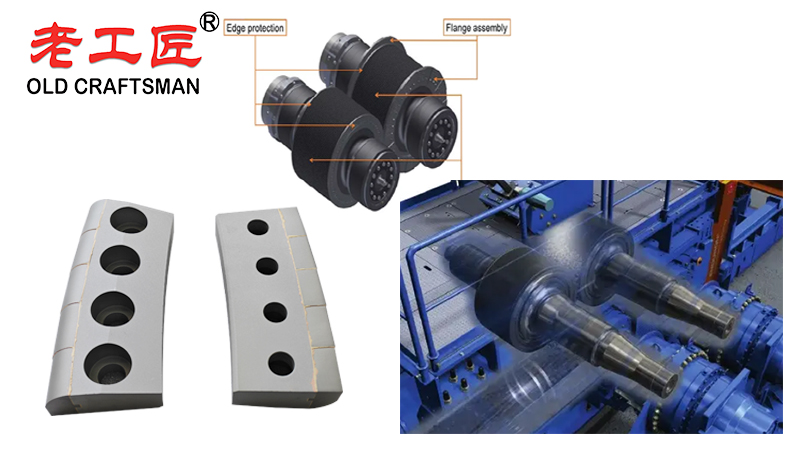

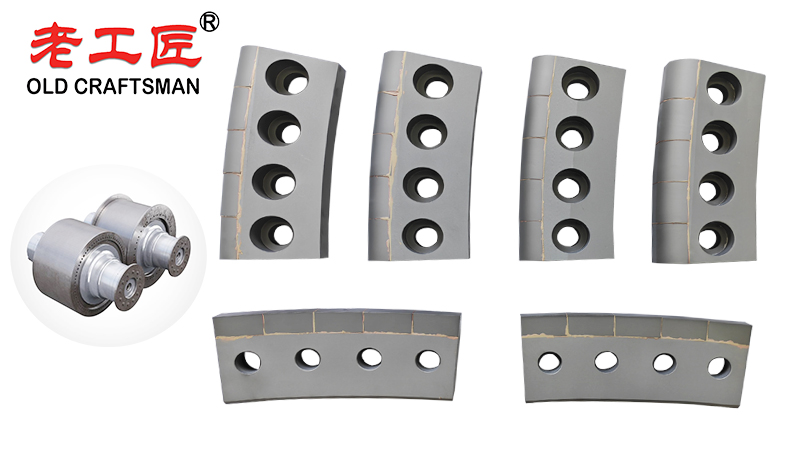

- Form Factor: Individually designed, pre-manufactured blocks or segments. They are not welded on but are mechanically fastened into precisely machined sockets on the roll’s main body (which can be made of a more cost effective, tough steel).

- “Custom” Nature: The “custom” aspect is critical. The blocks are engineered for:

- Specific Geometry: Designed to create and maintain the optimal roll profile for the life of the block.

- Specific Ore Characteristics: The grade of tungsten carbide (grain size, binder content) can be tailored for maximum wear resistance against the specific abrasiveness and impact of the processed ore.

- Specific HPGR Model: Designed to fit the exact dimensions and mounting system of the client’s HPGR machine.

Key Advantages: Why They Are the “Ultimate” Solution

1. Exceptional Wear Life & Reduced Downtime

- Up to 5-8x Longer Life: Tungsten carbide is vastly more wear resistant than hardened steel or weld overlays. This translates to months or even years of continuous operation between maintenance intervals.

- Massive Reduction in Downtime: The need for frequent roll re-surfacing or hardfacing is virtually eliminated. Maintenance cycles align with major plant shutdowns, maximizing production availability.

2. Maintained Operational Efficiency & Product Quality

- Consistent Roll Profile: The blocks are designed to wear very slowly and uniformly. This maintains the optimal nip angle and grinding gap throughout their life, ensuring a consistent product size distribution.

- Superior Edge Seal: Custom blocks are expertly profiled to maintain a tight seal with the cheek plates, minimizing edge leakage. This forces more material through the high-pressure zone, improving throughput and energy efficiency.

3. Enhanced Energy Efficiency

- By preventing side leakage and maintaining an optimal grinding profile, the HPGR operates at its design efficiency. More energy is directed into productive comminution rather than being wasted, reducing kWh per ton of processed ore.

4. Improved Cost-Per-Ton (CPT)

- While the initial capital outlay for custom carbide blocks is higher than traditional solutions, the Total Cost of Ownership (TCO) is significantly lower.

- Factors driving lower TCO:

- Greatly extended service life.

- Drastic reduction in labor and downtime costs for maintenance.

- Reduced energy consumption per ton.

- Consistent performance and higher availability.

5. Mechanical Attachment & Serviceability

- No Heat-Affected Zone (HAZ): Unlike welding, mechanical attachment does not subject the roll core to thermal stress, preserving its structural integrity.

- Modular Replacement: Worn or damaged individual blocks can often be replaced without removing the entire roll assembly, further reducing downtime.

Implementation & Considerations

Design and Installation Process:

- Application Analysis: Review of ore characteristics (abrasion index, moisture content), operating pressure, and required throughput.

- Roll Core Engineering: The roll body is machined to accept the custom blocks, often with a dovetail or similar secure locking mechanism.

- Block Fabrication: Tungsten carbide blocks are pressed, sintered, and ground to precise tolerances.

- Precise Installation: Blocks are fitted and locked into place on the roll core, ensuring a seamless, high-integrity surface.

Challenges and Considerations:

- Higher Initial Investment: The upfront cost is substantial.

- Potential for Brittle Fracture: While tough, tungsten carbide is more brittle than steel. It can be susceptible to chipping or cracking under extreme impact (e.g., from tramp metal). Proper roll protection systems (metal detection) are critical.

- Engineering Expertise Required: Successful implementation depends on precise design, manufacturing, and installation. Partnering with an experienced supplier is non-negotiable.

The HPGR Edge Block represents a highly cost effective solution for high pressure grinding rolls in the mineral processing industry across the worldwide. Manufactured from advanced, wear resistant materials with superior mechanical properties and exceptional high temperature stability, it delivers outstanding abrasion resistance and significantly extended life expectancy compared to conventional segments. This enhanced durability dramatically reduces downtime and maintenance costs while providing superior performance in the most demanding abrasive wear applications. Thanks to its optimized design and premium material properties, the HPGR Edge Block achieves substantial energy savings and reduced energy consumption, making it a smart long term investment in energy efficiency. Operators benefit from lower operational costs, higher throughput, and a rapid return on investment, establishing it as the high performance choice for companies seeking both immediate cost savings and sustainable, long-term reliability in severe wear environments.

Conclusion

For high tonnage, abrasive applications, custom tungsten carbide edge blocks are unequivocally the ultimate wear solution for HPGRs. They transform the wear component from a frequent maintenance liability into a predictable, high performance asset. By delivering unparalleled wear life, operational consistency, and the lowest possible cost-per-ton, this technology is a cornerstone for modern, efficient, and profitable mineral processing operations. The investment is strategically justified by the substantial returns in uptime, throughput, and energy savings.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding