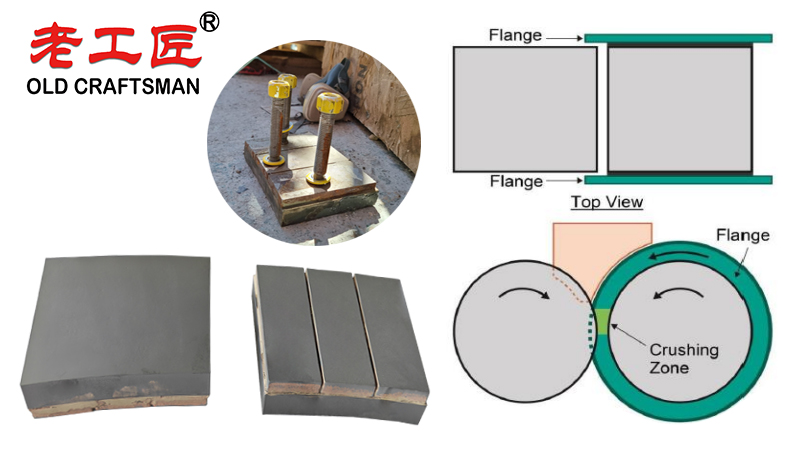

Understanding the Role and Environment of HPGR Flanges

First, it’s essential to understand what the flanges do. They are not the main wear surfaces (the studded tires are), but they are crucial components that:

- Contain the feed material in the compression zone.

- Protect the roll ends and the main bearings from abrasive dust and fines.

- Help create the high pressure environment necessary for particle-bed comminution.

They operate in an extremely hostile environment of high pressure, abrasive feed, and potential impact from oversize or foreign material.

Common Wear Issues: Identification, Causes, and Solutions

Here are the most common wear patterns, their likely causes, and actionable solutions.

1. Issue: Asymmetric or One-Sided Wear

- Identification: One flange is worn significantly more than the other, or wear is uneven across a single flange’s surface.

- Primary Cause: Misaligned Rolls. This is the most common cause. If the rolls are not parallel, the material flow and pressure distribution become uneven. One side will experience a higher pressure peak and more abrasive wear.

- Other Potential Causes:

- Uneven feed distribution across the roll width (e.g., a clogged chute or distributor).

- Uneven wear on the tires themselves, creating an irregular surface for the flanges to work against.

- A damaged or worn bearing on one side, allowing the roll to tilt.

- Troubleshooting and Solutions:

- Check Roll Alignment: This is the first and most critical step. Follow the manufacturer’s precise procedure for checking and adjusting roll parallelism.

- Inspect Feed Distribution: Observe the feed just before it enters the nip. The ore curtain should be even across the entire width of the roll. Check for and clear any blockages in the feed chute or distributor.

- Inspect Tires and Bearings: Look for corresponding uneven wear on the tires. Check bearing clearances and condition.

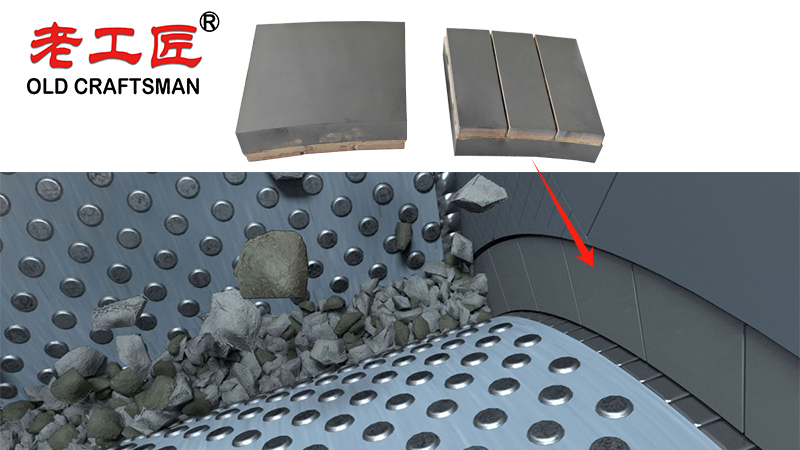

2. Issue: Excessive Abrasive Wear (General Loss of Material)

- Identification: The flange is wearing down uniformly but at a much faster rate than expected, shortening its service life.

- Primary Cause: Abrasion from fine, hard feed material. This is the fundamental wear mechanism, but the rate can be accelerated by several factors.

- Contributing Causes:

- Higher Abrasion Index (AI) of the ore than designed for.

- Operating at excessively high pressures for the given material, increasing the stress and wear on the flanges.

- Low Tungsten Carbide Grade Quality: Using flanges made from a sub-standard grade of carbide with low binder content or poor microstructure, reducing its abrasion resistance.

- Troubleshooting and Solutions:

- Optimize Operating Pressure: Run the HPGR at the minimum pressure required to achieve the desired product size and throughput. Higher pressure exponentially increases wear.

- Verify Feed Characteristics: If the ore’s Abrasion Index has changed significantly, you may need to adjust expectations for flange life or consider a different flange material specification.

- Upgrade Flange Material: Consult with your flange supplier. A switch to a more wear resistant tungsten carbide grade (e.g., a finer carbide grain size or a harder, more abrasion resistant formulation) might be justified despite a higher initial cost.

3. Issue: Impact Damage and Chipping

- Identification: Visible chunks or pieces broken out of the flange’s edge or surface. Cracks may be visible propagating from these points.

- Primary Cause: Impact from tramp metal or large, uncrushable oversize rock (e.g., a “scats” from the SAG mill). Tungsten carbide is very hard and abrasion resistant but is brittle and has low tensile strength, making it susceptible to impact damage.

- Contributing Causes:

- Ineffective Metal Detection: A failed or poorly maintained tramp metal detection system (magnetometer).

- Lack of/Inadequate Relief System: The mechanical relief system for uncrushables (e.g., the “floating roll” mechanism) may not be functioning correctly or may be too slow to react.

- Troubleshooting and Solutions:

- Enhance Feed Protection: This is paramount. Ensure the tramp metal detection system is functional, correctly calibrated, and has effective reject mechanisms. Regularly test it.

- Check Relief Systems: Verify that the hydraulic or spring-based relief system for the movable roll is functioning correctly and set to the appropriate pressure.

- Consider a Tougher Grade: For plants with chronic tramp metal issues, discuss with your supplier the possibility of using a “tougher” grade of carbide. These grades often have a higher cobalt binder content, which sacrifices a small amount of abrasion resistance for significantly improved impact resistance.

4. Issue: Thermal Cracking (“Heat Checking”)

- Identification: A network of fine, shallow cracks on the surface of the flange. In severe cases, pieces can spall off.

- Primary Cause: Thermal cycling. The repeated friction and pressure generate significant heat at the surface of the flange. When the HPGR cycles on and off, or if the feed stops while the rolls are still turning, the rapid heating and cooling creates thermal stress that exceeds the material’s strength, causing cracks.

- Contributing Causes:

- Frequent start-stop cycles.

- Running the rolls without feed (“running dry”), even for a short period.

- Troubleshooting and Solutions:

- Avoid Dry Running: Never allow the HPGR to run without a feed load. Interlock the rolls to stop if the feed conveyor stops.

- Minimize Cycling: Optimize process control to run the HPGR in continuous, steady state operation for as long as possible. Avoid unnecessary shutdowns.

- Operational Procedures: If a shutdown is necessary, follow proper procedures to allow the rolls to cool gradually if they have been under high load.

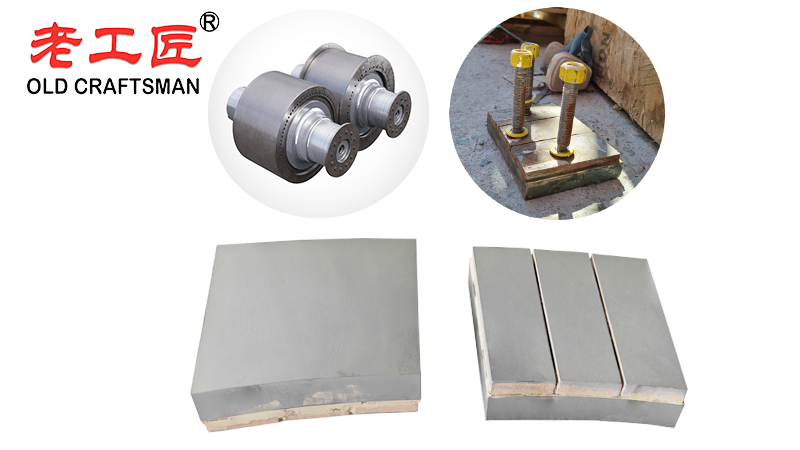

General Preventive Maintenance and Best Practices

- Regular Visual Inspection: Implement a strict schedule for inspecting flanges. Look for the early signs of the issues above. Catching misalignment or impact damage early can save a flange from catastrophic failure.

- Proper Installation: Ensure flanges are installed correctly and torqued to the manufacturer’s specifications. Incorrect installation can create stress points.

- Material Tracking: Keep detailed records of flange life (operating hours, tons processed) correlated with ore type. This data is invaluable for predicting life and justifying material or operational changes.

- Supplier Partnership: Work closely with a reputable tungsten carbide supplier. They can perform failure analysis on worn parts (often for free) and recommend the optimal material grade and design for your specific application.

Summary Table: Troubleshooting Quick Guide

| Wear Issue | Likely Cause | Immediate Action | Long-Term Solution |

|---|---|---|---|

| Asymmetric Wear | Roll Misalignment, Uneven Feed | Check and correct roll alignment & feed distribution | Improve maintenance procedures |

| Excessive Abrasive Wear | Very abrasive ore, High pressure | Optimize operating pressure | Upgrade to a higher-grade carbide |

| Chipping & Impact Damage | Tramp Metal, Oversize rocks | Inspect & test metal detection system | Enhance feed protection systems |

| Thermal Cracking | Dry running, Frequent cycling | Ensure no-load interlock is functional | Optimize process for continuous operation |

By systematically following this troubleshooting guide, you can significantly extend the life of your HPGR tungsten carbide flanges, reduce unscheduled downtime, and improve the overall efficiency of your comminution circuit.

Long-term exposure to high pressure work environments (HPGR) and high stress jobs is a well established risk factor for developing high blood pressure (hypertension) and other serious health problems, including heart disease and heart failure. When a person experiences chronic stress, the constant “blood pushing” against artery walls leads to persistently elevated blood pressure, with both systolic blood pressure and diastolic blood pressure remaining higher than normal, often falling into the official high blood pressure category.

Managing stress is therefore one of the most important steps to reduce stress related damage and lower the long term risk of cardiovascular issues. Simple, evidence based techniques such as deep breathing exercises, taking regular breaks (even in high temperature or intense workplaces), and learning to mentally “toggle” away from pressure can significantly help keep blood pressure readings in a healthier range.

While everyday tools like metal detectors have nothing to do with hypertension, the principle is similar: just as a detector alerts you to hidden risks, regular blood pressure monitoring alerts you to the hidden danger of chronic stress. By addressing stress early and consistently, you can protect your arteries from the long term effects of HPGR flange like constant high pressure and greatly reduce your chances of serious heart related problems.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding