In the demanding worlds of industrial processing, commercial kitchens, and serious food production, standard equipment simply won’t cut it. This is especially true for mixers and blenders tasked with intensive workloads pulverizing fibrous roots, crushing massive volumes of ice, grinding hard grains into fine flour, or homogenizing thick, dense concoctions hour after hour. For these applications, the blade isn’t just an accessory; it’s the heart of the operation and the most common point of failure.

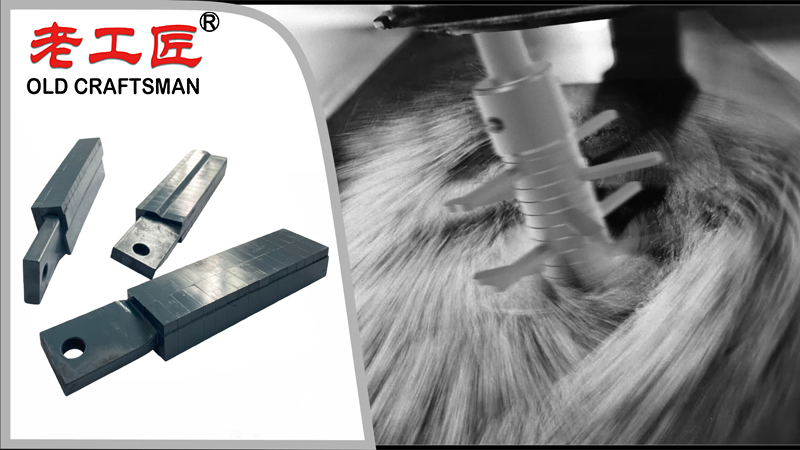

Enter Tungsten Carbide Blades. More than just an upgrade, this material represents a fundamental engineering leap, truly establishing itself as the ultimate solution for intensive mixer durability.

Why “Intensive” Workloads Demand a Superior Material

Standard stainless steel blades, even high quality ones, are plagued by limitations that become critically apparent under stress:

- Rapid Dulling: The constant abrasion from ice, frozen fruit, and fibrous materials (like ginger or celery) quickly wears down a steel edge. A dull blade doesn’t cut; it mashes and tears, increasing blend times, creating uneven textures, and generating heat that can damage nutrients and the motor.

- Fatigue and Failure: The high impact forces from crushing hard ingredients can cause microscopic cracks in steel, leading to bending, warping, or even catastrophic blade breakage.

- Corrosion Under Stress: Acids from citrus, tomatoes, and greens can pit and corrode a stressed steel surface. These tiny pits become breeding grounds for bacteria and create weak points that accelerate failure.

- Motor Strain: A dull or bent blade forces the mixer’s motor to work significantly harder to achieve the same result, leading to overheating, increased energy consumption, and premature motor burnout.

Tungsten Carbide: The Material Science of Superiority

Tungsten carbide is a ceramic metallic composite created by fusing tungsten particles with a carbon binder. This process results in a material with extraordinary properties:

- Extreme Hardness: Ranking between 8.5 and 9 on the Mohs scale (where diamond is 10), it is significantly harder than even the hardest treated steels (which typically max out around 8). This translates to near complete resistance to abrasive wear.

- High Density and Stiffness: It possesses immense structural integrity, meaning it will not flex, bend, or warp under extreme loads, maintaining perfect balance and alignment.

- Inert and Corrosion-Proof: It is completely non-reactive, impervious to all food acids, and will never rust or pit.

The Tangible Benefits for Intensive Applications

For any user pushing their equipment to the limit, the switch to a tungsten carbide blade delivers undeniable results:

1. Unmatched Longevity and Zero Downtime:

This is the primary benefit. A tungsten carbide blade can last up to 10 times longer than a premium steel blade in identical intensive conditions. For a commercial smoothie bar processing hundreds of orders daily or an industrial facility running continuous batches, this eliminates frequent blade changes, reduces maintenance costs, and prevents costly operational downtime.

2. Consistent Peak Performance, Batch After Batch:

Because the edge doesn’t dull, every blend is as efficient as the first. You get perfectly smooth textures, consistently fine particle sizes, and drastically reduced processing times, even with the hardest ingredients. There is no gradual decline in quality.

3. Ultimate Motor Protection:

A sharp blade encounters less resistance. By moving through material effortlessly, the tungsten carbide blade drastically reduces the torque load and amperage draw on the mixer’s motor. This prevents overheating, reduces energy costs, and significantly extends the life of the entire machine a benefit far exceeding the cost of the blade itself.

4. Uncompromising Food Safety and Hygiene:

The non-porous, corrosion proof surface cannot harbor bacteria. It is effortlessly cleaned and sanitized, meeting the highest standards for food safety in sensitive environments like commercial food production and healthcare facilities.

5. Superior Value Over Time:

While the initial investment is higher, the Total Cost of Ownership (TCO) is lower. You save money by not purchasing multiple replacement steel blades, reducing energy bills, avoiding motor repairs, and maximizing productivity through reliable performance.

Is a Tungsten Carbide Blade Right For You?

This upgrade is most critical for:

- Commercial & Industrial Users: Smoothie bars, juice chains, restaurant kitchens, food processing plants, and laboratory homogenization.

- Owners of High-Performance Blenders: (Vitamix, Blendtec, etc.) who regularly use them for their most challenging tasks.

- Home Users Who Demand the Best: If you frequently make nut flours, crush ice, process frozen foods, and want a true “lifetime” component.

The Verdict

For intensive applications, the question is no longer if a blade will fail, but when. Tungsten carbide blades change that equation. They are not a mere accessory but a core performance and durability upgrade. By solving the fundamental weaknesses of traditional blades dulling, corrosion, and fatigue they provide unmatched reliability, protect your valuable equipment, and ensure consistent, high-quality results under the most extreme conditions.

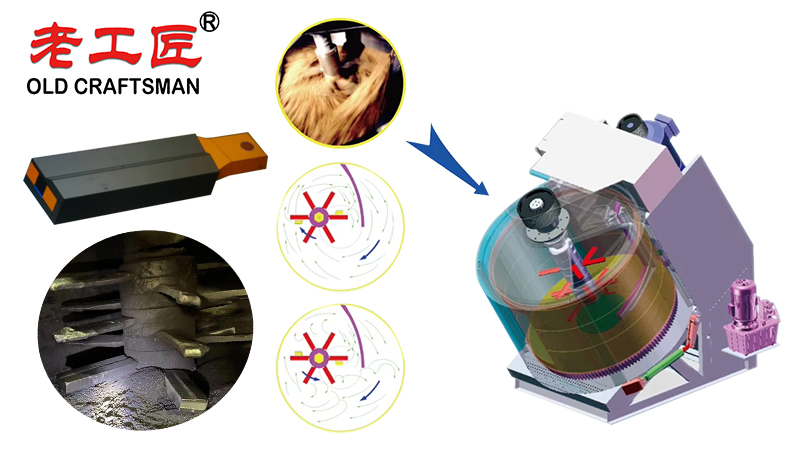

In carbide intensive mixers equipped with high torque three-phase motors, robust motor protection is critical due to the extreme mechanical loads, abrasive environment, stainless steel construction, and high ambient temperatures often exceeding 50 °C. To safeguard the motor against overload, short circuits, and ground faults, modern installations combine solid-state overload relays with inverse-time characteristics, electronic motor protection devices, and molded case circuit breakers (MCCB) that provide both thermal magnetic and short-circuit protection. For applications requiring precise speed control of the rotor and pan, variable frequency drives (VFDs) are widely used, incorporating built-in overload protection, phase loss detection, under/over-voltage protection, and ground fault monitoring. These solid-state VFDs not only extend blade life by enabling soft starting and reducing mechanical shock on tungsten carbide mixing tools, but also offer comprehensive single phase and phase-to-phase fault protection, ensuring reliable operation of the intensive mixer even under the harshest refractory, carbon paste, or battery material processing conditions in accordance with National Electrical Code (NEC) and IEC standards.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding