In the demanding world of industrial mixing, where raw materials are transformed into uniform compounds, the mixer blade is the heart of the operation. It’s the component that bears the brunt of the force, abrasion, and wear. For decades, operators have battled the high costs and downtime associated with frequent blade replacement. However, a superior solution has emerged and proven itself as the definitive answer: Tungsten Carbide (WC) Blades.

When it comes to maximizing the durability and efficiency of your intensive mixer, tungsten carbide blades are not just an upgrade they are the ultimate solution.

The Adversary: Why Standard Blades Fail

Traditional mixer blades are often made from hardened steel or alloys coated with wear resistant materials. In intensive mixing applications such as with carbon black, silica, glass fibers, minerals, or high fill polymers these blades face a relentless assault:

- Abrasive Wear: Hard, gritty particles constantly scrape and erode the blade surface, dulling its edges and changing its critical geometry.

- Impact Fatigue: Lumps of material or the sheer force of pushing against a dense batch causes micro fractures and deformation.

- Adhesive Wear: Sticky or chemically active compounds can “glue” to the blade, leading to buildup and inefficient mixing, which in turn increases torque and wear.

- Corrosion: Certain chemicals can corrode and pit the blade surface, accelerating mechanical wear.

The result? Standard blades wear down, leading to:

- Longer mix cycles and inconsistent batch quality.

- Increased energy consumption.

- Frequent production stoppages for blade replacement or refurbishment.

- Rising costs for spare parts and maintenance labor.

The Champion: The Unmatched Properties of Tungsten Carbide

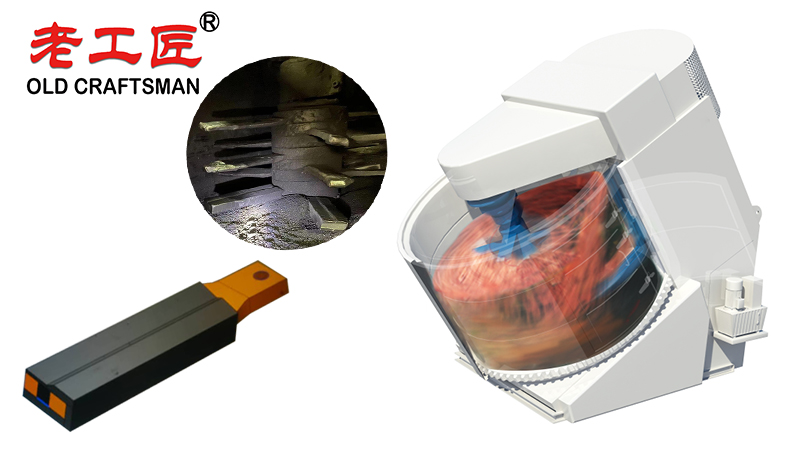

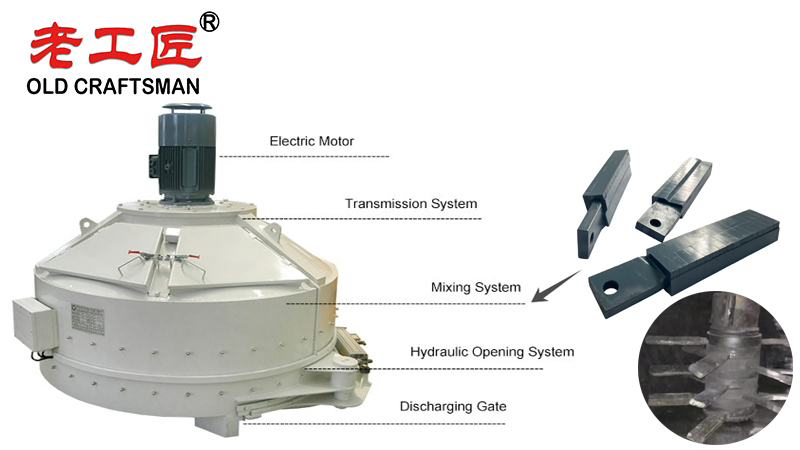

Tungsten carbide is a composite material consisting of tungsten carbide particles cemented together with a binder, usually cobalt. This structure gives it a set of properties that are perfectly suited for the extreme conditions inside an intensive mixer.

- Exceptional Hardness:

- Tungsten carbide ranks just below diamond on the Mohs hardness scale. It is significantly harder than the most abrasive fillers it encounters, meaning it resists wear and maintains its sharp, precision edge for vastly longer periods.

- Superior Abrasion Resistance:

- This is the core benefit. While a steel blade might be measured in weeks or months, tungsten carbide blades are measured in years. They can withstand the “sandpaper effect” of abrasive materials with minimal wear, ensuring consistent performance batch after batch.

- Impressive Strength and Rigidity:

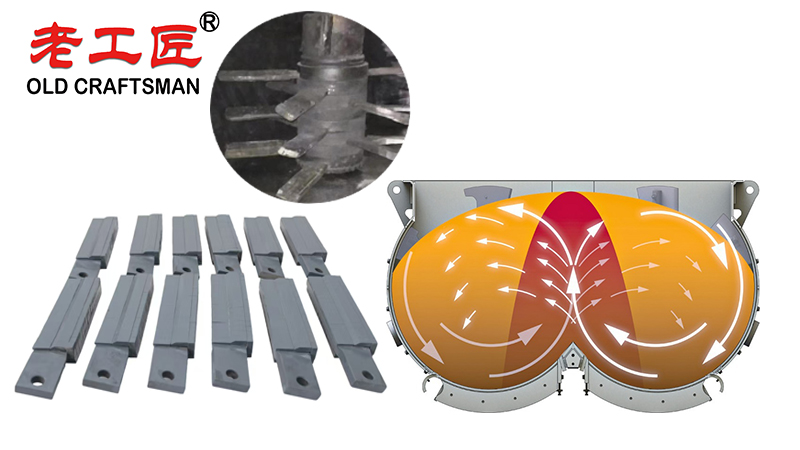

- Despite its extreme hardness, tungsten carbide has a very high modulus of elasticity (stiffness). It resists bending and deformation under the immense loads of an intensive mixer, maintaining the precise clearance between the blade and the chamber wall that is critical for efficient shear and mixing.

- Good Compressive Strength:

- It can bear tremendous compressive forces without cracking or deforming, making it ideal for high pressure mixing applications.

The Tangible Benefits for Your Mixing Operation

Switching to tungsten carbide blades transforms your mixer from a maintenance headache into a model of reliability and efficiency.

- Dramatically Extended Service Life: This is the most significant advantage. It’s not uncommon for tungsten carbide blades to last 10 to 20 times longer than their hardened steel counterparts. What was an annual replacement becomes a decadal one.

- Uncompromised Product Quality: As a blade wears, the mixing dynamics change. A tungsten carbide blade maintains its original geometry, ensuring every batch is mixed with the same shear, dispersion, and heat history as the first. This guarantees consistent product quality and reduces scrap rates.

- Maximized Uptime and Reduced TCO (Total Cost of Ownership): Fewer blade changes mean significantly less downtime. While the initial investment in tungsten carbide is higher, the dramatic reduction in replacement frequency, labor costs, and lost production time results in a much lower total cost of ownership over the life of the mixer.

- Improved Energy Efficiency: A worn steel blade has to work harder to achieve the same mix, drawing more power. A sharp, maintained tungsten carbide blade operates at peak efficiency, reducing energy consumption per batch.

Applications Where Tungsten Carbide is Non-Negotiable

While beneficial in many mixing applications, tungsten carbide blades are particularly critical in industries processing highly abrasive materials:

- Tire & Rubber Manufacturing: Carbon black, silica, and clay.

- Plastics & Composites: Fiberglass, minerals, talc, and ceramic fillers.

- Battery Production: Active cathode/anode powders.

- Ceramics & Advanced Materials: Silicon carbide, alumina, and other hard powders.

- Pharmaceuticals: Highly abrasive excipients.

Making the Switch: A Smart Long-Term Investment

When considering tungsten carbide blades, it’s important to view them as a long term capital investment rather than a simple spare part. Partner with a reputable manufacturer who can provide:

- Precision Engineering: Blades must be perfectly balanced and shaped to your specific mixer model.

- Expert Installation: Proper installation is crucial to avoid chipping and ensure optimal performance.

- Technical Support: Choose a supplier with the expertise to advise on the best solution for your specific material and process.

Conclusion

In the relentless environment of an intensive mixer, compromise on blade quality leads directly to compromised productivity and profitability. Tungsten carbide blades stand as the definitive engineering solution, offering unparalleled durability, consistency, and efficiency. By investing in tungsten carbide, you are not just buying a longer lasting part; you are investing in the relentless, uninterrupted performance of your entire mixing operation. It is, without a doubt, the ultimate solution for intensive mixer durability.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding