In the harsh world of mining, conveyor belts are the lifelines of material transport. They are subjected to extreme abrasion, heavy loads, and sticky, often abrasive materials like iron ore, coal, and copper concentrate. One of the most critical components for maintaining belt health, preventing material carryback, and ensuring operational efficiency is the primary belt cleaner or scraper. Among these, tungsten carbide-tipped (TCT) scrapers represent the pinnacle of performance and durability for the toughest applications.

What Are They?

Tungsten carbide scrapers are heavy-duty belt cleaning blades where the cutting edge is not made of steel or polyurethane, but of tungsten carbide a composite material known for being one of the hardest materials on earth, second only to diamond.

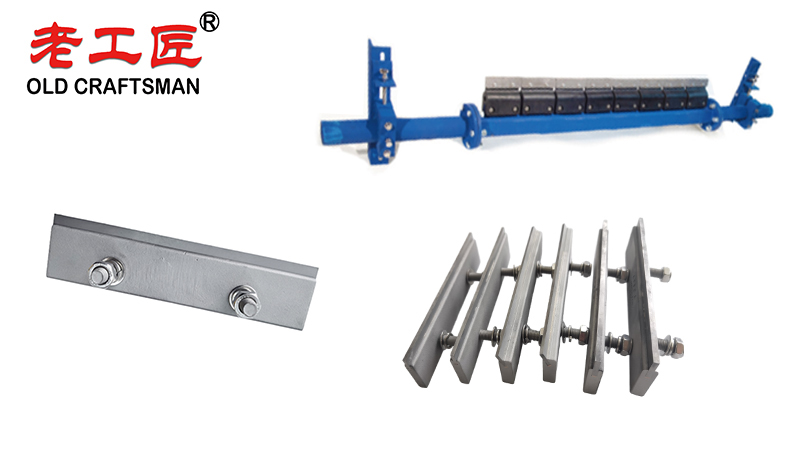

These scrapers typically consist of a robust steel holder or body that provides structural support and a means of mounting to the conveyor frame. Embedded into this holder are multiple tungsten carbide tiles or inserts that form the actual cleaning edge that contacts the belt.

Why Tungsten Carbide is the Superior Choice for Mining

- Extreme Hardness and Wear Resistance:

- Abrasion is the #1 enemy. Mining materials are highly abrasive. Tungsten carbide’s incredible hardness (~70-90 HRA) means it wears down at a fraction of the rate of polyurethane or steel blades. This translates to a blade life that can be 10 to 20 times longer than other materials.

- This reduces downtime for blade changes, a significant cost and safety benefit in a 24/7 mining operation.

- Effective Cleaning Under Extreme Conditions:

- Tungsten carbide blades maintain a sharp, consistent edge throughout their life. Unlike softer materials that can deform or wear unevenly, carbide provides continuous, effective scraping that minimizes carryback.

- This is crucial for preventing material buildup on rollers, frames, and pulleys, which can cause belt mistracking, premature component failure, and significant housekeeping issues.

- Chemical and Corrosion Resistance:

- Mining operations often use water for dust suppression and can encounter various chemicals. Tungsten carbide is highly resistant to corrosion, ensuring performance isn’t degraded in wet or chemically active environments.

- Cost-Effectiveness (Total Cost of Ownership):

- While the initial purchase price of a tungsten carbide scraper is higher than other types, the Total Cost of Ownership (TCO) is often lower.

- The dramatically extended service life means far fewer replacements are needed. This saves not only on the cost of the blades themselves but also on the massive labor costs and production losses associated with frequent maintenance stops on a major conveyor system.

Key Design Features for Tough Mining Applications

- Segmented Carbide Inserts: Instead of one long, brittle piece of carbide, high quality scrapers use multiple individual tiles. This allows for:

- Individual Replacement: If one tile is damaged, you don’t have to replace the entire blade.

- Flexibility: The segments can adjust slightly to minor inconsistencies in the pulley surface or belt tension, maintaining better contact.

- Shock Absorption: The steel holder absorbs impact shocks that could shatter a solid carbide blade.

- Precision Angling and Mounting System: The scraper must be mounted in a robust assembly (typically a “holder” or “cradle”) that allows for precise adjustment of the blade angle and pressure against the pulley. Proper installation is critical to maximize cleaning efficiency and prevent damage to the belt.

- Tungsten Carbide Grade: The specific grade of carbide used can be tailored. A higher cobalt content makes the insert tougher and more shock-resistant, while a lower cobalt content increases hardness and wear resistance for ultra abrasive applications.

Where Are They Used on a Mining Conveyor System?

They are primarily installed at the head pulley as the primary cleaner. This is the point where the belt changes direction and material is discharged. The scraper is positioned to clean the belt just after it leaves the pulley, removing any material that did not naturally discharge due to being wet, sticky, or fine.

Diagram of a Typical Primary Scraper Installation:

[ HEAD PULLEY ]

|

| (Belt Travel Direction -->

|

[ Tungsten Carbide Scraper ] --> (Scrapes carryback off the belt surface)

|

V

(Collected carryback falls into chute or hopper)

Critical Considerations for Implementation

- Proper Tension: Excessive blade pressure accelerates wear on both the blade and the belt cover. The goal is to use the minimum effective pressure to clean the belt. Modern torsion arm mounting systems help automate this.

- Pulley Condition: The scraper requires a clean, cylindrical, and undamaged pulley surface to work effectively against. A damaged or built-up pulley will prevent proper blade contact.

- Belt Safety: While highly effective, the extreme hardness of carbide requires correct installation. If the blade is not properly angled or is over-tensioned, it can potentially cause excessive wear to the belt cover over time. Always follow the manufacturer’s guidelines.

- Secondary Cleaning: A complete belt cleaning system is multi staged. The tungsten carbide scraper is the primary defender, but it should be followed by secondary (e.g., brush style) and tertiary cleaners (e.g., belt ploughs) for a comprehensive solution.

Our mining conveyor belt scraper systems are specifically designed for the harshest environments, offering exceptional abrasion resistance and impact resistance when handling highly abrasive materials. Manufactured using high quality, heat resistant materials such as reinforced plastic and stainless steel, these scrapers maintain outstanding mechanical properties even under extreme temperatures and high temperature conditions. Through advanced manufacturing processes, we achieve a wide range of tensile strength while ensuring every component delivers high performing, long lasting durability in the most demanding specific applications within the mining industry. The carefully selected material properties guarantee reliable performance, reduced wear, and minimal downtime, making our scraper systems the ideal choice for heavy duty conveyor operations worldwide.

Conclusion

For mining operations where conveyor uptime, safety, and efficiency are paramount, tungsten carbide scrapers are not just an option; they are a strategic investment. Their unparalleled wear life and effective cleaning performance under the most punishing conditions directly translate to reduced maintenance costs, less wasted material, cleaner sites, and higher overall system productivity. When specifying a cleaner for the head pulley of a critical mining conveyor, tungsten carbide is the industry standard choice for tackling the toughest jobs.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding