Tungsten carbide (WC) is one of the hardest materials available, making it ideal for wear-proofing applications in industries like mining, machining, oil & gas, and manufacturing. Enhancing productivity with tungsten carbide wear-proofing involves optimizing material selection, design, and application techniques. Here’s how you can maximize efficiency:

1. Choose the Right Grade of Tungsten Carbide

- Coarse-Grain vs. Fine-Grain:

- Coarse-grain carbide offers better impact resistance (ideal for mining, drilling).

- Fine-grain carbide provides higher hardness and wear resistance (best for precision machining).

- Cobalt Content:

- Higher cobalt (6-12%) improves toughness but reduces hardness.

- Lower cobalt (3-6%) increases wear resistance but may be brittle.

2. Optimize Coating & Surface Treatments

- CVD/PVD Coatings: Apply thin layers of TiN, TiCN, or Al₂O₃ to further enhance wear resistance.

- Laser Cladding: For high-wear parts, laser-clad tungsten carbide extends lifespan significantly.

- Thermal Spraying: HVOF (High-Velocity Oxygen Fuel) spraying deposits dense, wear-resistant carbide layers.

3. Improve Component Design

- Edge Preparation: Chamfered or rounded edges reduce chipping.

- Reinforced Structures: Use carbide inserts in high-stress zones (e.g., drill bits, cutting tools).

- Modular Designs: Replaceable carbide tips reduce downtime in mining & machining.

4. Implement Efficient Machining & Grinding

- Use Diamond Tools: Only diamond grinding wheels can effectively shape tungsten carbide.

- Optimize Cutting Parameters: Lower speeds with high feed rates reduce thermal cracking.

- Coolant Use: Prevent overheating during machining to avoid micro-cracks.

5. Preventive Maintenance & Monitoring

- Regular Inspections: Check for cracks, wear patterns, and edge degradation.

- Predictive Replacement: Replace components before catastrophic failure (e.g., in oil drill bits).

- Ultrasonic Testing: Detect internal flaws in critical carbide parts.

6. Application-Specific Enhancements

- Mining & Drilling: Use carbide-tipped picks and buttons for longer service life.

- Machining Tools: Indexable carbide inserts with optimized geometries improve cutting efficiency.

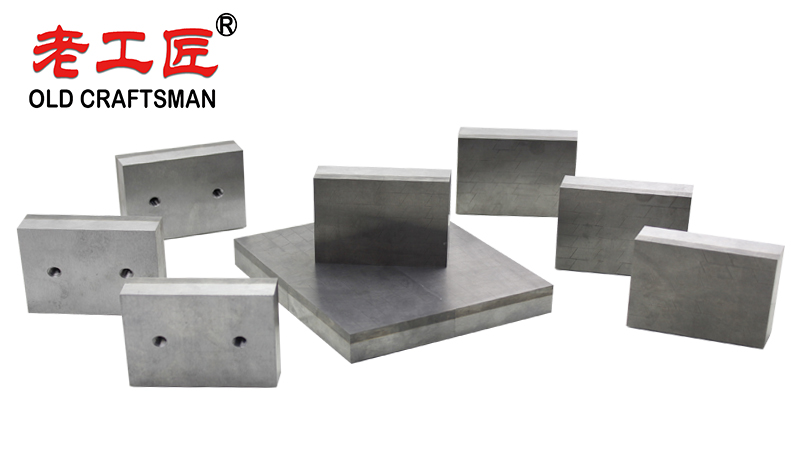

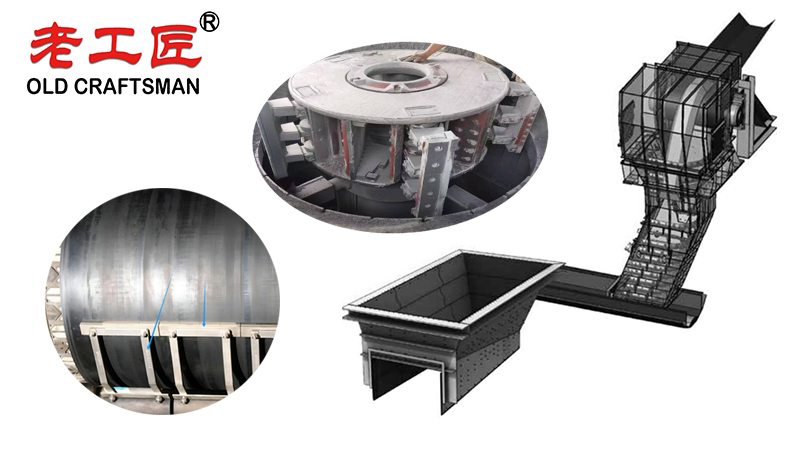

- Wear Plates & Liners: Carbide-reinforced plates in slurry pumps & conveyors reduce downtime.

7. Cost-Effective Strategies

- Rebuilding Worn Parts: Regrind or recoat carbide tools instead of full replacement.

- Bulk Purchasing: High-volume orders reduce per-unit costs.

- Hybrid Solutions: Combine carbide with ceramics or steel where full carbide isn’t necessary.

Conclusion

By selecting the right carbide grade, applying advanced coatings, optimizing design, and maintaining components properly, you can significantly enhance productivity in wear-intensive applications. Tungsten carbide’s extreme hardness and durability make it a key material for industries where wear resistance directly impacts operational efficiency.

Would you like recommendations for a specific application (e.g., mining tools, industrial blades, or machining inserts)?

Looking Forward to EXPOMIN 2025

EXPOMIN 2025 is a fantastic opportunity for us to connect with the mining community, share our expertise, and explore new partnerships. We are particularly excited to engage with clients and partners in Chile, a country at the forefront of the global mining industry. Join us in Santiago to discover how ZZ OLD CRAFTSMAN can help you achieve greater efficiency, sustainability, and profitability in your mining operations.

Stay tuned for more updates as we prepare for EXPOMIN 2025. Follow us on ZZ OLD CRAFTSMAN Social Media Links, for the latest news and insights from our team. We can’t wait to see you in Santiago!

Blet scarper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining mold operate Refractory Brick Mold Secondary belt cleaner scraper stresses VSI VSI crusher wear plates welding work