Tungsten carbide wear resistant liners play a critical role in mining machinery by protecting key components from wear, abrasion, and damage, thereby enhancing equipment performance and longevity. Their primary functions include:

1.Protection Against Abrasion and Erosion

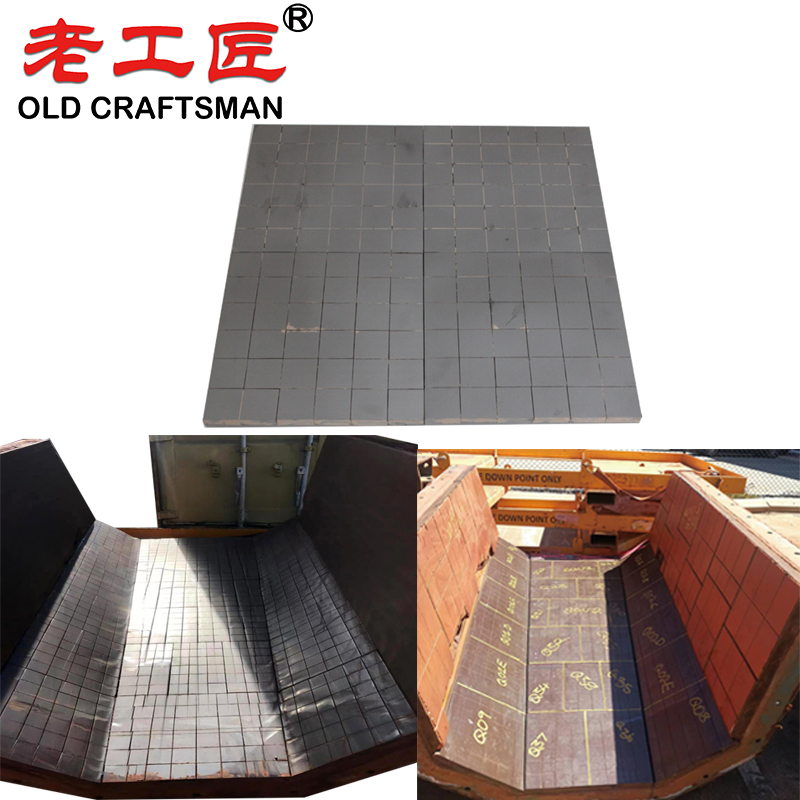

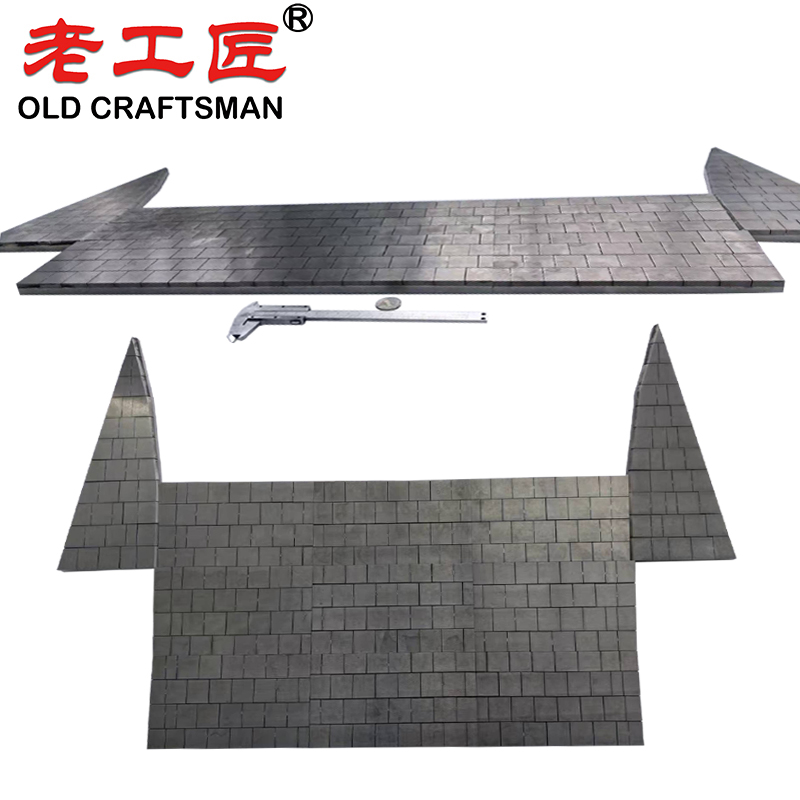

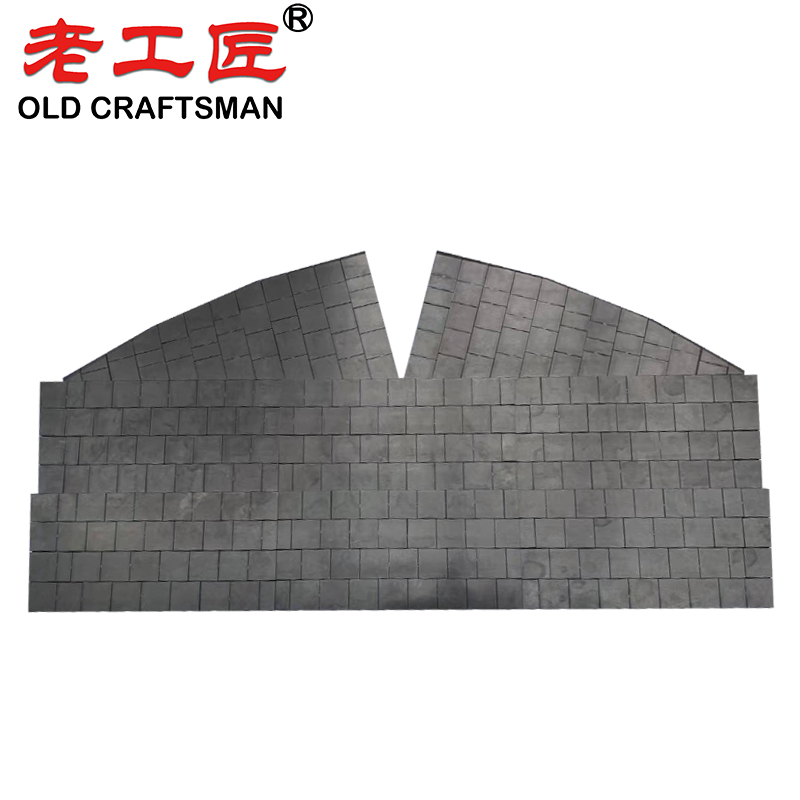

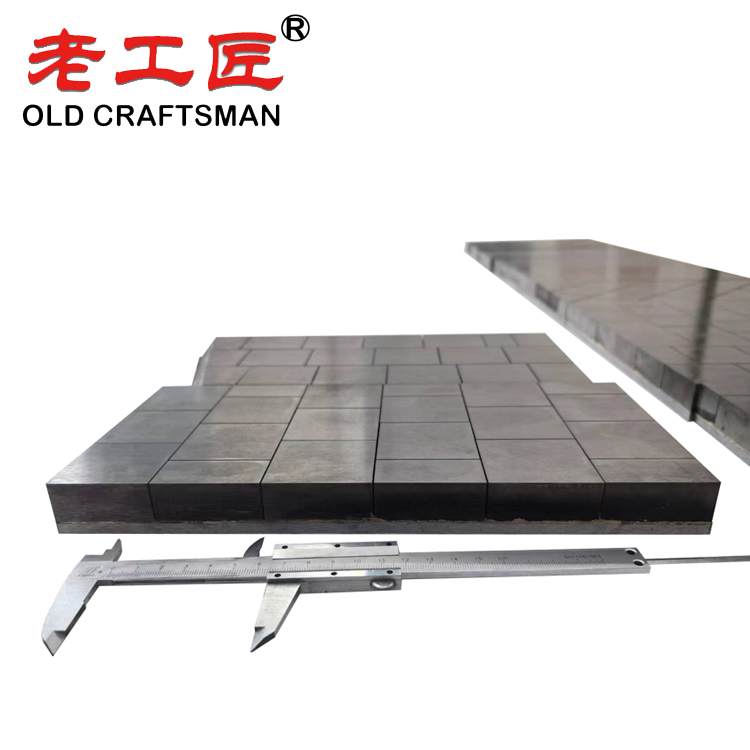

- In machines like grinding mills, crushers, and slurry pumps, tungsten carbide liners shield the inner surfaces from the constant grinding and scraping caused by hard ores, rocks, or abrasive slurries. Their exceptional hardness (e.g., tungsten carbide based alloys) resists material loss, preserving the machine’s structural integrity.

2.Extending Equipment Lifespan

- By acting as a sacrificial layer, these liners absorb the wear that would otherwise degrade the machine’s base material. This reduces the frequency of repairs or replacements, extending the operational life of equipment such as chutes, hoppers, and pipelines.

3.Maintaining Operational Efficiency

- Tungsten carbide liners help maintain consistent machine performance by preventing excessive wear that could alter the shape or dimensions of critical components (e.g., the grinding chamber of a ball mill). This ensures optimal throughput and reduces energy waste caused by inefficiencies.

4.Reducing Downtime and Maintenance Costs

- Their durability minimizes the need for frequent shutdowns for maintenance or part replacement. In high wear environments, such as mineral processing plants, this translates to significant cost savings and improved productivity.

5.Resistance to Harsh Conditions

- In addition to abrasion, tungsten carbide liners withstand corrosion, high temperatures, and chemical exposure common in mining operations (e.g., wet processing or acidic environments). This makes them vital for machines handling corrosive slurries or operating under extreme conditions.

6.Impact Mitigation (to an Extent)

- While not as impact resistant as materials like high manganese steel, certain tungsten carbide formulations provide moderate toughness, helping to cushion components like crusher jaws or mill liners from the repetitive impacts of ore processing.

In essence, tungsten carbide wear resistant liners serve as a robust barrier in mining machinery, safeguarding vital parts from the relentless wear and tear of processing abrasive materials. They ensure machines operate reliably and efficiently, supporting the demanding nature of mineral extraction and processing.

In the field of extractive metallurgy, iron ore processing plants rely on advanced techniques to efficiently recover valuable ore minerals from mineral resources. The process typically begins with crushing and grinding using heavy machinery operating at high speeds, reducing particle size to liberate minerals while withstanding high temperatures and abrasive conditions. Subsequent stages involve gravity separation and magnetic separation in the processing plant to concentrate the iron ore. To enhance operational efficiency and minimize operating costs, high performance wear resistant solutions, such as mining carbide wear liners, are essential for protecting equipment from intense abrasion and impact, ensuring reliable performance and extended service life in demanding environments.

In the mineral processing industry, mining operations whether open pit or underground handle large volumes of ore and waste rock with a wide range of particle sizes. The processing plant must separate valuable minerals through multiple processes that involve intense material handling, high temperatures, and severe abrasion. To ensure long term reliability and keep operating costs low, key pieces of equipment such as chutes, hoppers, crushers, screens, and pumps are protected with high quality, wear resistant carbide wear liners. These cost effective liners deliver outstanding abrasion resistance even when the process operates under extreme conditions, significantly extending equipment life, reducing downtime, and minimizing environmental impact by lowering the need for frequent replacements and excess energy consumption.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding