Are you searching for a mold that combines unbeatable strength, precision, and longevity for your refractory brick production? Look no further! Our Cemented Carbide Refractory Brick Molds are engineered to elevate your manufacturing process to the next level, delivering exceptional performance in even the most demanding high-temperature environments.

Advantages of ZZ Old Craftsman Cemented Carbide Molds:

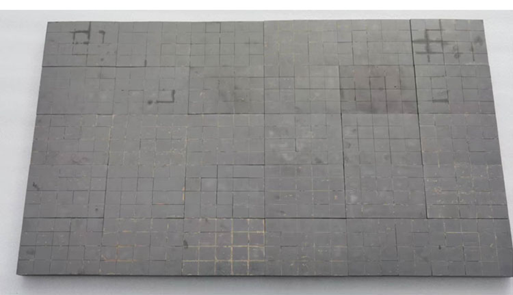

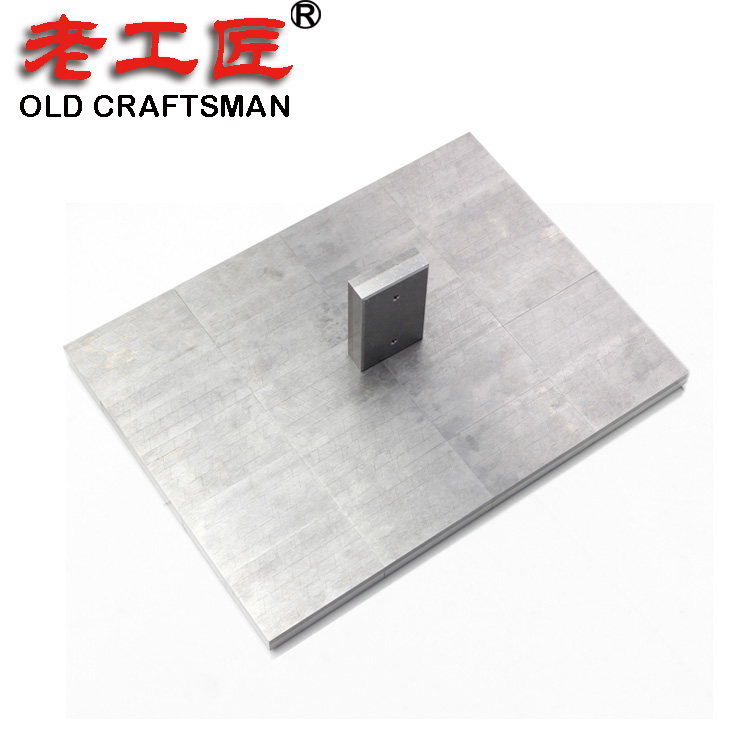

- Unmatched Durability: Crafted from premium cemented carbide, our molds are designed to withstand extreme heat, wear, and corrosion. Say goodbye to frequent replacements and hello to long-term reliability.

- Superior Precision: Achieve perfectly shaped refractory bricks every time. Our molds are meticulously engineered to ensure consistent dimensions and flawless finishes, meeting the strictest industry standards.

- High-Temperature Resistance: Built to thrive under intense heat, these molds maintain their structural integrity, making them ideal for producing top-quality refractory bricks used in furnaces, kilns, and beyond.

- Cost-Efficient Performance: With exceptional wear resistance and a prolonged lifespan, our molds reduce downtime and maintenance costs, maximizing your production efficiency and profitability.

- Customized Solutions: We understand that every project is unique. That’s why we offer tailored mold designs to meet your specific requirements, ensuring seamless integration into your workflow.

Applications of Tungsten Carbide Refractory Brick Molds

- Steel Industry: For lining blast furnaces, ladles, and tun-dishes.

- Glass Manufacturing: For creating bricks used in glass melting furnaces.

- Cement Production: For kiln linings and other high-temperature zones.

- Ceramics: For shaping bricks used in ceramic kilns and firing processes.

The Competitive Edge

In an industry where performance and reliability are paramount, our tungsten carbide refractory brick molds set a new standard. They are not just tools—they are investments in your production process, ensuring consistent quality and efficiency.

Join the Revolution in Refractory Brick Production

Upgrade your manufacturing process with the unparalleled strength and precision of tungsten carbide molds. Contact us today to request a quote or schedule a consultation. Let us help you achieve excellence in every brick you produce.

Your Success, Our Priority.

Choose Tungsten Carbide Refractory Brick Molds—where innovation meets durability.to industrial clients, and includes a strong call to action. Let me know if you’d like any adjustments!

Tungsten carbide (WC) is the primary raw material for manufacturing high-quality carbide refractory brick molds and cost-effective cutting tools, thanks to its exceptional wear resistance and ability to maintain a long-term cutting edge even under high temperatures. The production process begins with fine powder preparation, followed by precise mixing, pressing in refractory brick molds, and high-temperature sintering in a reducing atmosphere to achieve maximum density and performance. To minimize waste and reduce production costs, modern factories employ advanced quality control systems, optimized inventory management, and a combination of batch production for custom orders and semi-continuous production lines for standard items. Through continuous improvement initiatives (such as lean manufacturing and real-time process monitoring), manufacturers can deliver superior wear-resistant products at a lower total cost while maintaining consistent high quality across the entire production line.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding