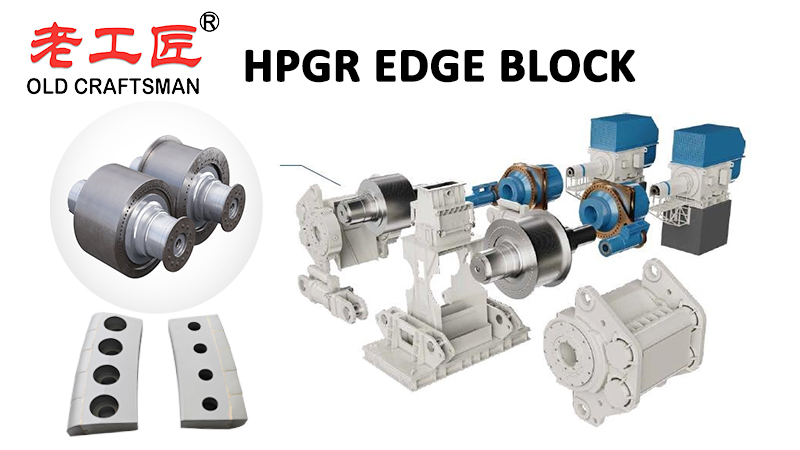

High Pressure Grinding Rolls (HPGR) technology has become increasingly important in mineral processing and cement production due to its energy efficiency and ability to produce finer particle sizes. The performance and longevity of HPGRs heavily depend on the quality of their wear components, particularly tungsten carbide edge blocks.

The Critical Role of Tungsten Carbide Edge Blocks

Tungsten carbide edge blocks serve as:

- The primary wear surface in HPGR operations

- Protection for the roll surfaces against abrasive materials

- Key components determining operational efficiency and maintenance intervals

Advantages of High-Quality Tungsten Carbide Edge Blocks

- Extended Service Life: Premium carbide formulations can last 2-3 times longer than standard grades

- Improved Grinding Efficiency: Maintain consistent gap dimensions for longer periods

- Reduced Downtime: Fewer replacements mean higher equipment availability

- Cost Savings: Lower total cost of ownership despite higher initial investment

Key Quality Factors for Optimal HPGR Performance

Material Composition

- Optimal balance of tungsten carbide grains and cobalt binder

- Consistent microstructure with minimal defects

- Custom formulations for specific ore characteristics

Manufacturing Precision

- Tight dimensional tolerances for proper fitting

- Uniform surface finish to prevent stress concentrations

- Advanced sintering processes for maximum density

Mechanical Properties

- High hardness (typically 85-93 HRA)

- Superior fracture toughness

- Excellent compressive strength

Implementation Considerations

When upgrading to high quality tungsten carbide edge blocks:

- Conduct a thorough wear analysis of current operations

- Select the appropriate carbide grade for your specific material

- Ensure proper installation by trained technicians

- Monitor performance to validate ROI

The implementation of HPGR Edge Block technology delivers exceptional long-term wear resistance and proves highly cost effective across demanding grinding processes in mineral processing plants. By optimizing operating parameters and providing real-time data, it significantly enhances productivity, quality, and overall utilization rate while reducing operational and production costs. This high efficiency solution drives process improvements, supports continuous improvement initiatives, increases production capacity, and improves operational efficiency measures, enabling plants to achieve sustainable high quality output with lower total ownership costs and superior production processes performance.

Conclusion

Investing in high-quality tungsten carbide edge blocks unlocks the full potential of HPGR technology by maximizing operational uptime, improving energy efficiency, and reducing long term operating costs. The superior wear resistance and mechanical properties of premium carbide grades make them a strategic choice for operations looking to optimize their comminution processes.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding