1. Carbide grade selection and quality control:

1) The carbide grade we currently used is finally determined through constant adjustments based, which can well meet the on-site use. We can also choose different alloy grades according to the wear conditions of different positions to balance the wear of each position.

2) Our alloy raw materials are all purchased from brand suppliers, and we conduct a comprehensive analysis of each batch of raw materials, and use MES and ERP to control the production process to ensure that each batch of products can be traced.

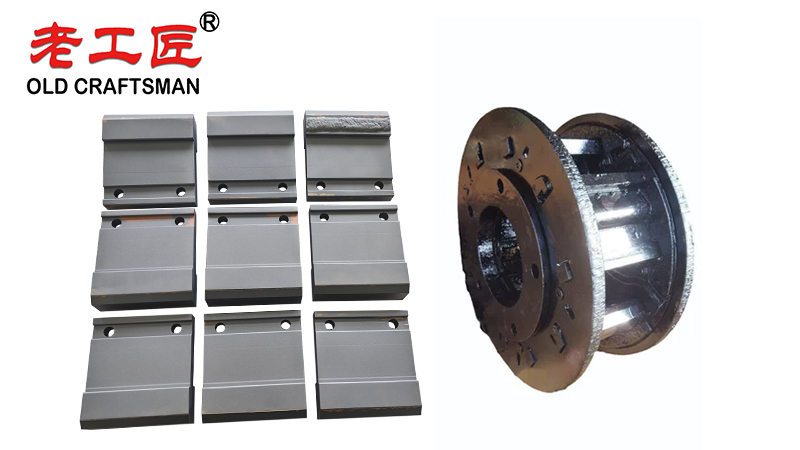

2. Treatment of brazing internal stress:

Frankly speaking, the brazing of cemented carbide and steel is very easy, but how to deal with the internal brazing stress is a worldwide problem. In the past 8 years, we have done a lot of experiments and cooperated with Chinese colleges in research and development, including the material of cemented carbide, brazing process, brazing structure and heat treatment process, which are several comprehensive factors that affect the internal stress.

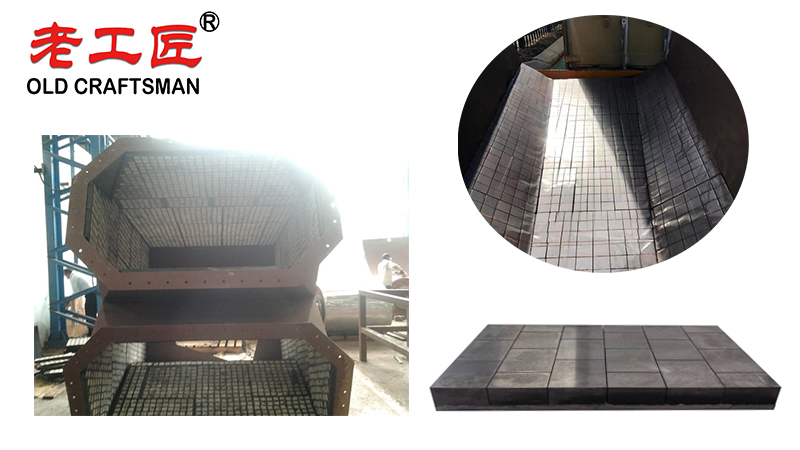

3. Brazing strength

If the brazing strength is not strong enough, will cause the alloy to fall off, which directly affects the service life of the wear plates and the replacement time of the entire conveyor transfer system.

Tungsten carbide wear parts are renowned for their exceptional performance in demanding applications, particularly where wear resistance is paramount. While stainless steels and tool steels offer a wide range of properties through the addition of alloying elements, they often fall short in extreme abrasive environments. This is where tungsten carbide excels, maintaining its hardness and integrity from room temperature up to much higher temperatures than most ferrous metals, including cast iron.

The superiority of tungsten carbide stems from its fundamental properties and specialized manufacturing processes. Its extremely high melting point is a key factor, far exceeding those of steel alloys. This intrinsic characteristic allows components like cutting edges and wear liners to resist deformation and thermal softening under intense frictional heat. The material’s formidable hardness is derived from its fine grain size, which is carefully controlled during production through powder metallurgy techniques.

In contrast, the properties of traditional steels are heavily dependent on thermal treatment processes. These are complex cycles involving heating the metal is heated to a specific temperature, often followed by being rapidly cooled (quenched) and then tempered. Processes like hardening and annealing can significantly alter a steel’s microstructure, making a cold worked material softer or a brittle one tougher. However, even the best heat-treated steels cannot match the wear life of tungsten carbide in severe conditions.

While the initial cost of tungsten carbide is higher, its unparalleled durability and longevity in high-temperature, high-wear scenarios make it a remarkably cost-effective solution over time. It reduces downtime for part replacement and maintains operational efficiency where conventional metals would rapidly degrade. Therefore, for the most challenging industrial applications involving abrasion, impact, and elevated temperatures, tungsten carbide wear parts provide an unmatched combination of performance and lifetime value, outperforming even advanced steel alloys.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding