Tungsten carbide (WC) is a hard, dense, and wear-resistant ceramic material widely used in industrial applications. Here are its key properties:

Physical Properties:

- Hardness: Extremely hard (~9–9.5 Mohs, ~2200–2600 HV), second only to diamond and boron carbide.

- Density: High (~15.6 g/cm³), making it very heavy.

- Melting Point: ~2,870°C (5,198°F), excellent for high-temperature applications.

- Thermal Conductivity: Moderate (~110 W/m·K), helps dissipate heat.

- Thermal Expansion: Low (~5.2–7.0 × 10⁻⁶ /K), resists thermal deformation.

Mechanical Properties:

- Compressive Strength: Very high (~6 GPa), resists crushing forces.

- Stiffness: High Young’s modulus (~530–700 GPa), rigid and deformation-resistant.

- Fracture Toughness: Moderate (6–12 MPa·√m), brittle compared to metals but tougher than most ceramics.

Chemical Properties:

- Corrosion Resistance: Resistant to acids and oxidation at room temperature but degrades in oxidizing environments at high temperatures.

- Chemical Stability: Inert to many chemicals but reacts with strong oxidizers (e.g., nitric acid).

Electrical & Magnetic Properties:

- Electrical Conductivity: Conducts electricity (~2×10⁶ S/m), unlike most ceramics.

- Magnetic Properties: Weakly magnetic when containing cobalt binder.

Applications:

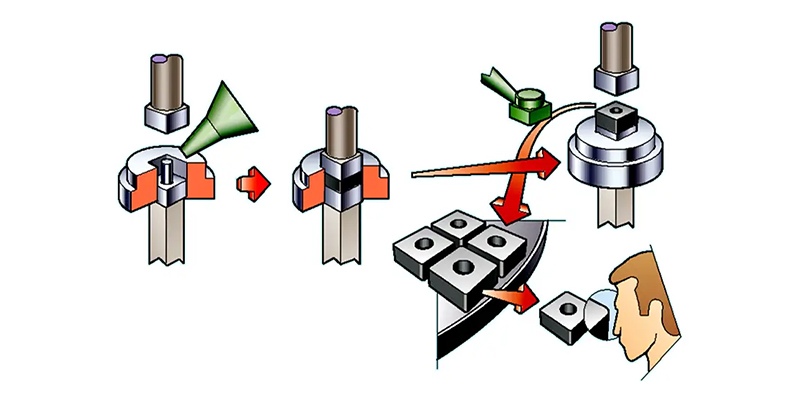

- Cutting tools (drill bits, inserts)

- Wear-resistant parts (nozzles, dies)

- Mining & construction (rock drills)

- Armor-piercing ammunition

- Jewelry (due to scratch resistance)

Limitations:

- Brittle: Prone to chipping under impact.

- Expensive: High production costs.

- Heavy: Not ideal for weight-sensitive applications.

Tungsten carbide is often combined with a cobalt (Co) or nickel (Ni) binder in cemented carbide forms to improve toughness while maintaining hardness.

These properties make tungsten carbide ideal for cutting tools, wear-resistant parts, jewelry, and high-performance industrial applications. Tungsten carbide’s unique combination of hardness, heat resistance, corrosion resistance, and durability makes it a go-to material across industries. Its ability to maintain performance under extreme conditions reduces costs, enhances reliability, and supports precision in both industrial and consumer applications.

Tungsten carbide is a high-performance material renowned for its exceptional mechanical properties, including outstanding hardness, high strength, and superior tensile strength even at room temperature. It maintains excellent dimensional stability and remarkable impact resistance under extreme conditions, making it highly resistant to wear in corrosive environments and capable of withstanding high temperatures without losing its properties over the long term. Thanks to its excellent thermal conductivity and robustness, tungsten carbide produced from high-quality carbide powders is widely used in the manufacture of high-precision cutting tools and wear-resistant components. Although the initial manufacturing process is complex and the raw material is not cheap, its extraordinary durability and performance deliver superior cost effectiveness throughout the product lifecycle, far surpassing conventional steel or other plastic materials in demanding industrial applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding