Carbide, specifically tungsten carbide, is the preferred material for mining conveyor belt scrapers due to its exceptional combination of hardness, wear resistance, and overall cost effectiveness in the long run. It’s a classic case of “you get what you pay for,” where a higher initial investment leads to significantly lower total operating costs.

Here’s a detailed breakdown of why carbide outperforms other materials like steel, urethane, or ceramic.

The Core Problem: Abrasive Wear

In mining, conveyor belts carry incredibly abrasive materials like iron ore, coal, copper ore, and gravel. The primary job of a scraper (or “belt cleaner”) is to remove this sticky, abrasive material from the belt to prevent carryback, which causes mess, belt mistracking, and roller damage.

This creates a constant, high stress abrasion battle. Softer scraper blades wear down quickly, losing effectiveness and requiring frequent replacement.

Why Carbide Wins: Key Advantages

1. Superior Hardness and Wear Resistance

- The Hardness Factor: Tungsten carbide is one of the hardest materials available for industrial use, second only to diamond in many cases. On the Rockwell C Hardness (HRC) scale:

- Steel Blades: Typically HRC 45-55. They wear down relatively quickly.

- Urethane Blades: Very soft in comparison; they work by flexing but abrade fast.

- Ceramic Blades: Very hard (HRC 70+), but can be brittle.

- Tungsten Carbide Blades: Extremely hard (HRA 90+, which is approximately HRC 80+). This extreme hardness makes it highly resistant to abrasion.

- Result: A carbide tipped scraper blade can last 10 to 20 times longer than a standard steel blade and significantly longer than urethane or ceramic. This translates to months or even years of service instead of weeks.

2. Unique Self-Sharpening Property

This is a critical advantage. Carbide blades are often designed with a specific geometry or are made from carbide impregnated materials.

- How it Works: As the blade wears, the hard tungsten carbide particles are exposed. Softer binding materials (like cobalt) wear away slightly faster, leaving the ultra-hard carbide particles protruding. This creates a microscopically rough, sharp surface that is exceptionally effective at scraping.

- Benefit: The blade maintains optimal cleaning efficiency throughout its entire lifespan, unlike steel blades that become dull and rounded, reducing their effectiveness soon after installation.

3. Dramatically Reduced Downtime and Maintenance

In mining, downtime is incredibly expensive. Every minute a conveyor is stopped for maintenance is a minute of lost production.

- Because carbide blades last so much longer, the frequency of scraper replacement plummets.

- This means fewer maintenance shutdowns, reduced labor costs for replacements, and less risk of injury for maintenance crews.

4. Better Belt Life and Protection

This might seem counterintuitive wouldn’t a harder material damage the belt? When properly installed and tensioned, the opposite is true.

- An ineffective, worn steel or urethane blade allows abrasive material to build up. This carryback then gets caught in rollers and pulleys, causing belt mistracking and gouging, which damages the belt far more than a clean scrape.

- A sharp, efficient carbide blade removes nearly 100% of the material, protecting the belt from this secondary damage. It cleans cleanly without gouging the belt surface.

5. Cost-Effectiveness (Lower Total Cost of Ownership – TCO)

While a single carbide scraper blade has a much higher initial purchase price than a steel or urethane blade, its Total Cost of Ownership is far lower.

TCO Calculation Includes:

- Cost of the blades.

- Labor cost for replacement.

- Cost of production downtime during replacement.

- Cost of belt damage from ineffective cleaning.

When all these factors are considered, carbide is almost always the most economical choice for high abrasion mining applications.

Comparison with Other Materials

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Tungsten Carbide | Extreme wear resistance, self-sharpening, long life, low TCO. | High initial cost, can be brittle on impact. | Primary scrapers in high abrasion mining (ideal application). |

| Steel | Low initial cost, high strength. | Wears very quickly, becomes dull, high replacement frequency. | Light duty or secondary scrapers; temporary solutions. |

| Urethane / Polyurethane | Good flexibility, gentle on belts, corrosion resistant. | Wears quickly in highly abrasive conditions, ineffective against packed material. | Less abrasive materials, food industry, secondary cleaners. |

| Ceramic | Very hard and wear resistant. | Brittle, can shatter upon impact, often more expensive than carbide. | Applications where fine, dry abrasives are present. |

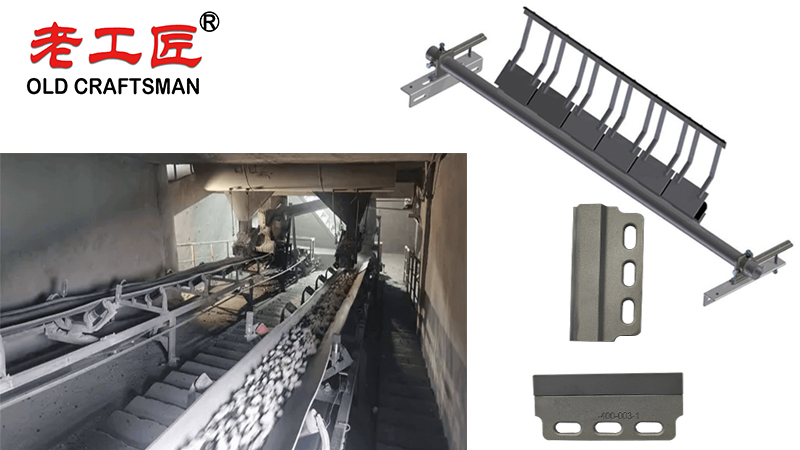

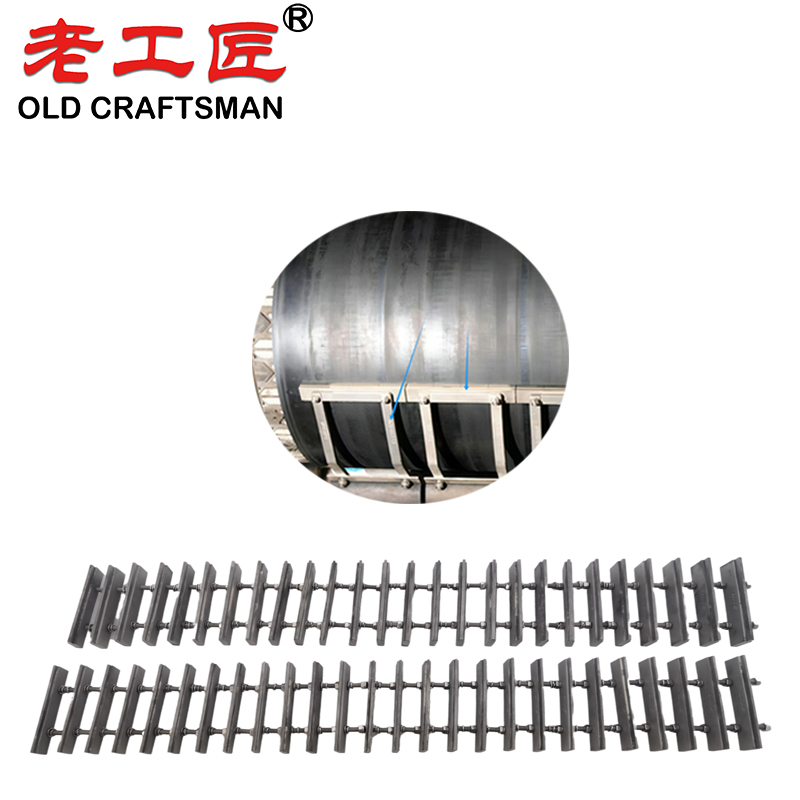

A high-quality mining carbide conveyor belt scraper, made from premium hardened tool steels and advanced stainless steels, delivers exceptional abrasion resistance and dramatically extended service life in the harshest material handling environments.

Specifically designed for heavy duty belt conveyor systems handling highly abrasive materials such as coal, ore, and aggregates, these scrapers effectively remove stubborn residue while minimizing material loss and belt wear. The core tungsten carbide inserts, combined with hardened steel substrates, achieve superior Rockwell hardness values, ensuring outstanding resistance to depth of penetration even under extreme temperatures and continuous impact.

This combination of resistant materials provides high performance cleaning over the long term, significantly improves efficiency, reduces downtime, and lowers maintenance costs across a wide range of specific applications in the mining and bulk material handling industries.

Conclusion

Carbide is the preferred material for mining conveyor belt scrapers because it directly addresses the primary challenge of the application: extreme abrasive wear. Its unparalleled hardness and unique self-sharpening characteristic ensure maximum cleaning efficiency and an exceptionally long service life. By minimizing downtime, maintenance labor, and secondary belt damage, carbide provides the lowest total cost of ownership, making it the smartest and most reliable choice for the demanding world of mining.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding