ZZ OLDCRAFTSMAN’s Tungsten Carbide Chute Wear Liners (carbide wear plates) are an excellent choice for industries requiring high wear resistance, durability, and extended service life in abrasive environments. Here’s why you should consider them:

✅ 1. Superior Wear Resistance

- Made from high grade tungsten carbide (WC), one of the hardest materials (HV 1500+), ensuring exceptional resistance to abrasion, erosion, and impact.

- Ideal for mining, cement, steel, and power plants where materials like coal, ore, and slag cause rapid wear.

✅ 2. Extended Lifespan

- Lasts 5-10 times longer than standard steel or ceramic liners, reducing downtime and replacement costs.

- Maintains structural integrity even under extreme conditions.

✅ 3. Impact & Corrosion Resistance

- Withstands heavy impacts from large, sharp edged materials.

- Resistant to chemical corrosion, oxidation, and high temperatures (up to 600°C).

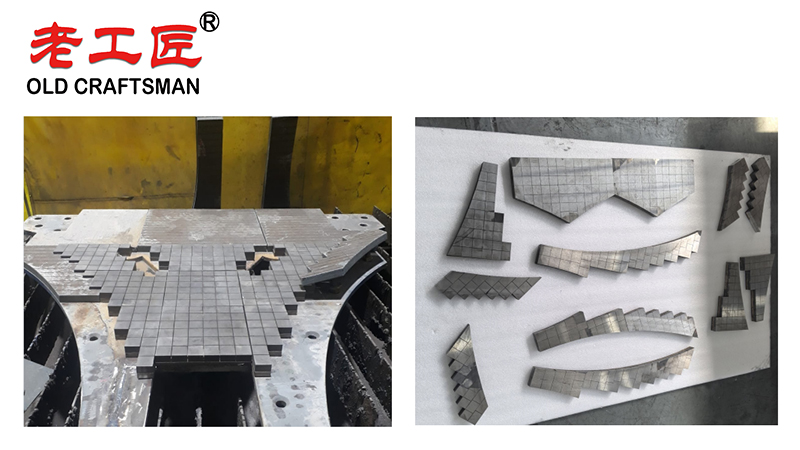

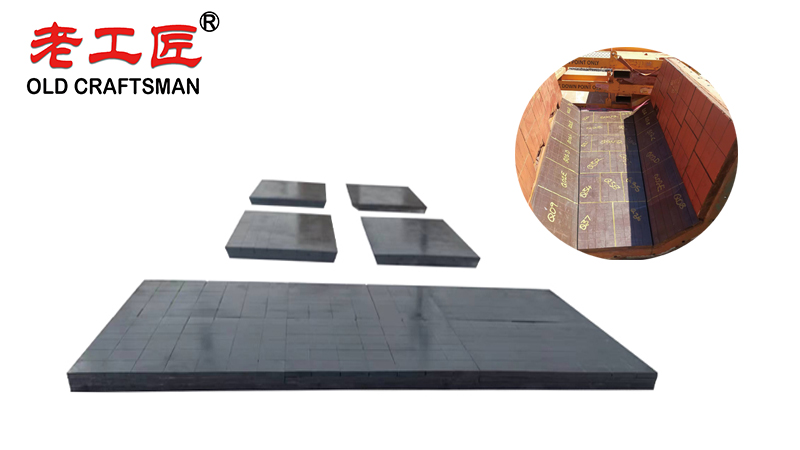

✅ 4. Customizable Solutions

- Available in various shapes, sizes, and configurations (tiles, plates, or embedded designs) to fit different chute geometries.

- Can be bolted, welded, or bonded for easy installation.

✅ 5. Cost-Effective in the Long Run

- Higher upfront cost but saves money over time due to reduced maintenance and replacement frequency.

- Minimizes production stoppages, improving operational efficiency.

✅ 6. Trusted Brand Reliability

- ZZ OLDCRAFTSMAN is known for high quality industrial wear solutions, backed by rigorous testing and proven performance in harsh applications.

Ideal Applications:

✔ Mining & Quarrying (Ore, Coal, Gravel)

✔ Cement & Steel Industry (Clinker, Slag)

✔ Power Plants (Ash Handling Systems)

✔ Any High-Abrasion Material Handling

Applications involving severe sliding abrasion and medium impact, such as

- Chutes

- Deflector chutes

- Ore Handling Systems

- Liner Plates

- Hoppers

- Conveyor skirts

- Conveyor drag plates

- HPGR feed cheek plates

- HPGR flange

In the harsh conditions of iron and steel production, mining carbide chute liners are considered high quality wear parts. They are commonly used in places like steel mills and blast furnaces. They are designed for very harsh conditions. These high quality, high strength liners are manufactured from advanced wear resistant materials that deliver exceptional high abrasion resistance and high performance impact resistance even under prolonged exposure to high temperatures across a wide range. Mining carbide has special properties. When it is combined with stainless steel or aluminum, it creates a protective oxide layer. This layer offers excellent corrosion protection. It also greatly reduces material loss over time. This outstanding material’s ability to withstand harsh environments ensures extended service life and minimized downtime in the most aggressive material handling applications within the iron and steel industry.

Conclusion:

Mining Tungsten Carbide Wear Liners offer outstanding abrasion resistance for resistant materials that demand high strength. Their production process creates a material that is very strong and performs well. It has great mechanical properties and excellent resistance in iron ore testing. Mechanical engineers choose them over stainless steel in blast furnaces and basic oxygen furnaces, making them the top material to resist steel products wear applications.

Let me know if you want the same paragraph but shorter (5 lines), longer (for a brochure), or translated into Chinese. Happy to adjust instantly.

If you need long lasting, ultra durable carbide chute liners that outperform steel, rubber, or ceramic alternatives, ZZ OLDCRAFTSMAN’s tungsten carbide liners are a smart investment for maximizing productivity and minimizing wear related failures.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding