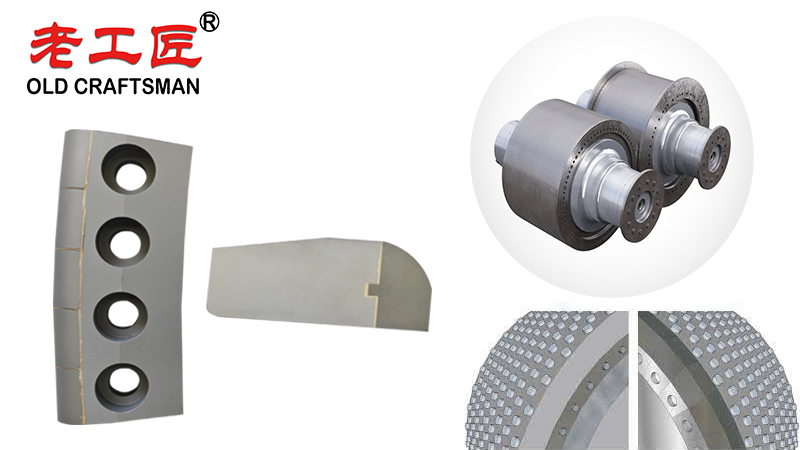

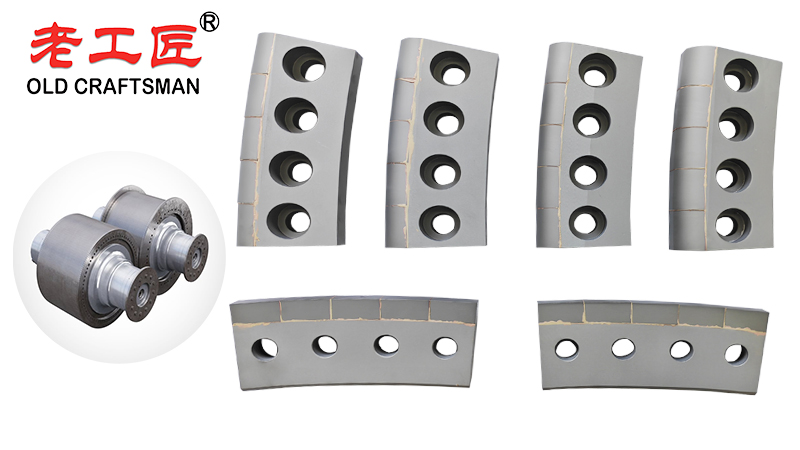

High-Pressure Grinding Rolls (HPGR) edge blocks made of tungsten carbide (WC) outperform other materials due to their exceptional combination of hardness, wear resistance, toughness, and thermal stability. Here’s why:

1. Extreme Hardness & Wear Resistance

- Tungsten carbide has a Vickers hardness of ~1,500–2,200 HV, far exceeding hardened steel (~800 HV) or ceramic alternatives.

- This hardness minimizes abrasive wear from hard ores (e.g., iron, diamond, copper), extending service life significantly.

2. High Compressive Strength

- WC can withstand 6,000+ MPa compressive strength, making it ideal for HPGR applications where extreme pressures (50–300 MPa) are applied.

- Unlike steel, which deforms under prolonged stress, WC maintains structural integrity.

3. Superior Fracture Toughness

- While ceramics (e.g., alumina) are hard, they are brittle. WC has higher fracture toughness (8–12 MPa√m), resisting crack propagation under cyclic loading.

- This prevents catastrophic failure during high pressure grinding operations.

4. Thermal & Chemical Stability

- WC retains strength at elevated temperatures (up to 500–600°C), reducing thermal fatigue risks.

- It resists oxidation and corrosion better than steel, especially in wet or chemically aggressive ore processing.

5. Reduced Downtime & Maintenance Costs

- Longer lifespan than steel or ceramic alternatives means fewer replacements, lowering operational costs.

- Consistent performance maintains grinding efficiency over time, improving throughput.

Comparison with Alternatives

| Material | Hardness (HV) | Toughness (MPa√m) | Compressive Strength (MPa) | Wear Resistance | Thermal Stability |

|---|---|---|---|---|---|

| Tungsten Carbide | 1,500–2,200 | 8–12 | 6,000+ | ★★★★★ | ★★★★★ |

| Hardened Steel | 600–800 | 10–20 | 2,500–3,500 | ★★★☆☆ | ★★★☆☆ |

| Alumina Ceramic | 1,500–2,000 | 3–5 | 2,000–3,000 | ★★★★☆ | ★★★★☆ |

HPGR Edge Blocks are critical wear parts in high pressure grinding rolls (HPGR) that operate under extreme conditions, including high temperature and intense mechanical action. The material selection for these edge blocks plays an important role in achieving long service life and high performance. The ability of a material to maintain its mechanical properties particularly high compressive strength and tensile strength at elevated temperatures is essential. Superior abrasion resistance and a low coefficient of friction further reduce wear rates across a wide range of ore types and operating conditions. Heat resistant stainless steel grades and advanced hard facing alloys are commonly evaluated using standardized test methods to measure their physical properties, high strength, and overall durability under combined thermal and mechanical loads, ensuring reliable protection of the roll surface throughout extended operational campaigns.

Conclusion

Tungsten carbide edge blocks are the optimal choice for HPGRs due to their unmatched wear resistance, strength, and durability. While initial costs are higher than steel, their extended lifespan and reduced downtime provide better long term ROI in mining and mineral processing applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding