The impact of regular and thorough carbide cheek plate inspections is not just essential; it is absolutely critical for the safe, efficient, and profitable operation of an HPGR. They are a primary defense against catastrophic failure.

Here’s a detailed breakdown of why these inspections are so vital:

1. To Prevent Catastrophic Failure and Major Damage

This is the most important reason. The cheek plates are not just wear parts; they are a fundamental safety containment system.

- Their Role: The cheek plates (or end frames) are located on either side of the rolls. Their primary job is to contain the rock feed within the crushing zone (the “nip”) and prevent material from bypassing the rolls and entering the bearing and seal assemblies.

- The Consequence of Failure: If a carbide tile becomes loose, cracks, or wears through completely, extremely hard and abrasive feed material can rapidly escape into the internal components of the HPGR.

- Domino Effect: This abrasive material will quickly destroy the intricate and extremely expensive labyrinth seals. Once the seals are gone, abrasive dust will contaminate the hydrostatic bearings, which operate with microscopic clearances. The result is almost certain catastrophic bearing failure, which can lead to damage to the rolls themselves and the main frame of the HPGR.

- Cost of Neglect: The cost of a set of cheek plate tiles is significant. However, the cost of replacing bearings, seals, and possibly rolls, plus the extensive unplanned downtime (often weeks), is orders of magnitude higher.

2. To Protect Massive Capital Investments

An HPGR is a multi-million dollar piece of capital equipment. The cheek plates are a relatively small investment designed to protect the much larger investments:

- Rolls: The rolls themselves, often fitted with tungsten carbide studs, are the single most expensive component of the HPGR.

- Bearings and Seals: The hydrostatic bearing systems are highly engineered, precision, and very costly.

- Main Frame: Damage from a catastrophic failure can even impact the main structural frame of the machine.

Regular inspections are a classic case of “a stitch in time saves nine.” Replacing a $20,000 cheek plate assembly on schedule is far better than causing $500,000+ in damage to bearings and rolls.

3. To Maintain Operational Efficiency and Throughput

The condition of the cheek plates directly impacts the performance of the HPGR.

- Bypassing and Bypass Leakage: As the tiles wear, the gap between the tile and the roll edge increases. This allows more feed material to bypass the crushing zone. This material is not crushed, reducing the throughput and overall efficiency of the circuit.

- Power Draw and Specific Energy: Bypassed material means the rolls are not working at their designed capacity, leading to sub-optimal power draw and reducing the energy efficient advantage that is a key reason for selecting an HPGR.

- Product Size Distribution: Increased bypass can lead to a coarser product size, which can negatively impact downstream processes (e.g., ball mill throughput in a grinding circuit).

4. To Enable Predictive Maintenance and Schedule Downtime

HPGRs are typically run in continuous, 24/7 operations where unplanned downtime is devastating to production targets.

- Scheduled vs. Unscheduled Downtime: By regularly inspecting cheek plate wear (e.g., measuring tile thickness, checking for cracks or loose tiles), maintenance planners can accurately predict the remaining service life.

- Planning and Preparation: This allows them to order replacement parts in advance and schedule the change-out during a planned maintenance shutdown. This is infinitely preferable to an emergency stop that halts the entire crushing circuit and forces crews to work overtime.

5. To Ensure Personnel Safety

A failure of the cheek plates can be a significant safety hazard.

- Ejection of Material: A sudden failure can cause high-velocity ejection of rock and metal fragments.

- Structural Integrity: The forces involved in an HPGR are enormous (several thousand kN). A catastrophic failure could potentially compromise the machine’s structural integrity, creating a dangerous situation for personnel nearby.

Regular inspections are a key part of a proactive safety culture, ensuring the machine’s protective systems are intact.

What Does a Proper Inspection Entail?

A thorough inspection is more than just a visual glance. It should include:

- Visual Inspection: Looking for cracks, chips, or broken tiles.

- Wear Measurement: Using calipers or depth gauges to measure the remaining thickness of the carbide tiles, especially in the high-wear zones. This is compared to the minimum safe thickness specified by the OEM.

- Check for Looseness: Tapping tiles to check for a hollow sound that indicates they have debonded from the backing plate.

- Check Fasteners: Ensuring all bolts and retaining hardware are tight and secure.

- Documentation: Recording findings to track wear rates over time and build a historical database for better predictive maintenance.

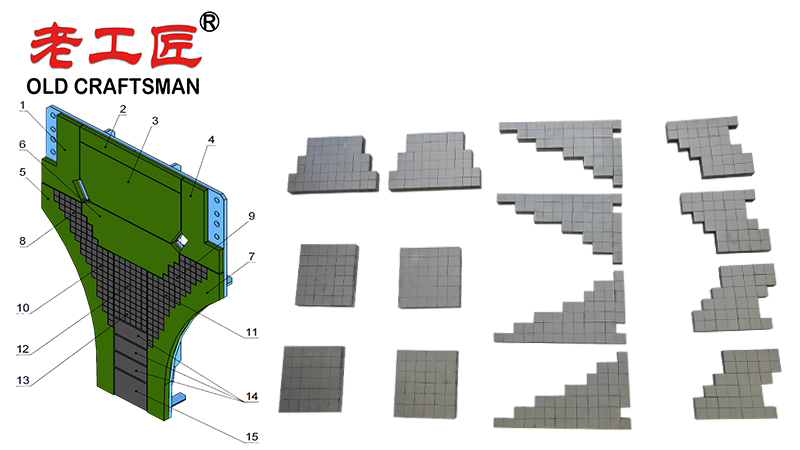

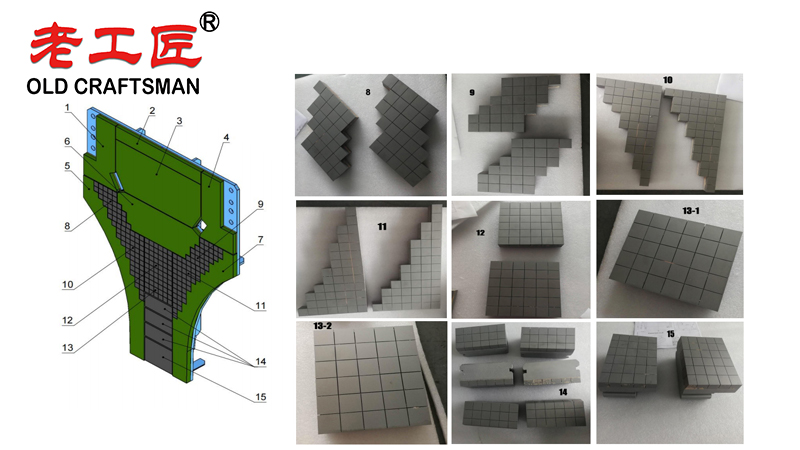

In the demanding industrial applications of high pressure grinding rolls (HPGR), cheek plates are critical components designed to protect the roller edges from severe wear. These heavy duty cheek plates are typically manufactured using tungsten carbide or silicon carbide inserts embedded in a stainless steel base, sometimes incorporating synthetic diamond plates on the most exposed cut edges to dramatically extend service life.

The primary function of HPGR cheek plates is to resist the extreme lateral forces and abrasive wear generated when raw material is fed between the counter rotating rollers under very high pressure. Common abrasives in the feed stream, such as quartz (a natural abrasive), aluminum oxide, or other hard mineral particles, act as bonded or loose abrasive grains that aggressively remove material from unprotected surfaces.

Without proper protection, excessive heating, abrasive grain embedment, and mechanical overload can rapidly lead to various types of failure, including cracking, spalling, chipping of the cut edges, or even catastrophic bearing failure in the HPGR unit due to misalignment caused by worn cheek plates. The use of ultra-hard tungsten carbide, silicon carbide, or synthetic diamond plates significantly improves resistance to these wear mechanisms, making them the preferred choice for the most severe operating conditions in mining and cement processing.

Conclusion

Think of carbide cheek plate inspections not as an optional task, but as a non-negotiable, critical preventive measure. They are the essential early warning system that protects the heart of the HPGR from catastrophic and expensive damage. The small investment of time and resources required for regular inspections pales in comparison to the astronomical costs and production losses associated with a failure they could have prevented.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding