Tungsten Carbide blades are essential because they offer an unparalleled combination of extreme hardness, wear resistance, and toughness. In the punishing environment of a heavy duty mixer, where abrasive and dense materials are processed, standard steel blades would wear down rapidly, leading to contamination, inconsistent product quality, and frequent, costly downtime for replacements. Tungsten Carbide blades dramatically extend service life, maintain mixing integrity, and provide a superior return on investment.

The Detailed Breakdown: The “Why” Behind the Essential Nature

To understand why Tungsten Carbide is so critical, let’s compare it to the challenges faced in a heavy duty intensive mixer.

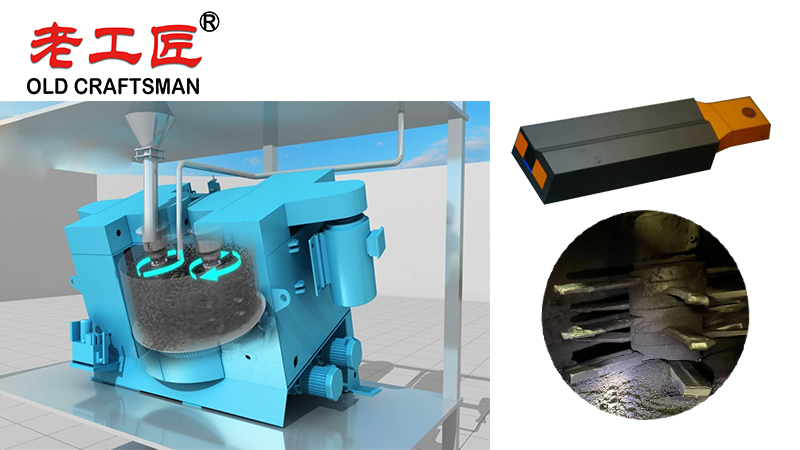

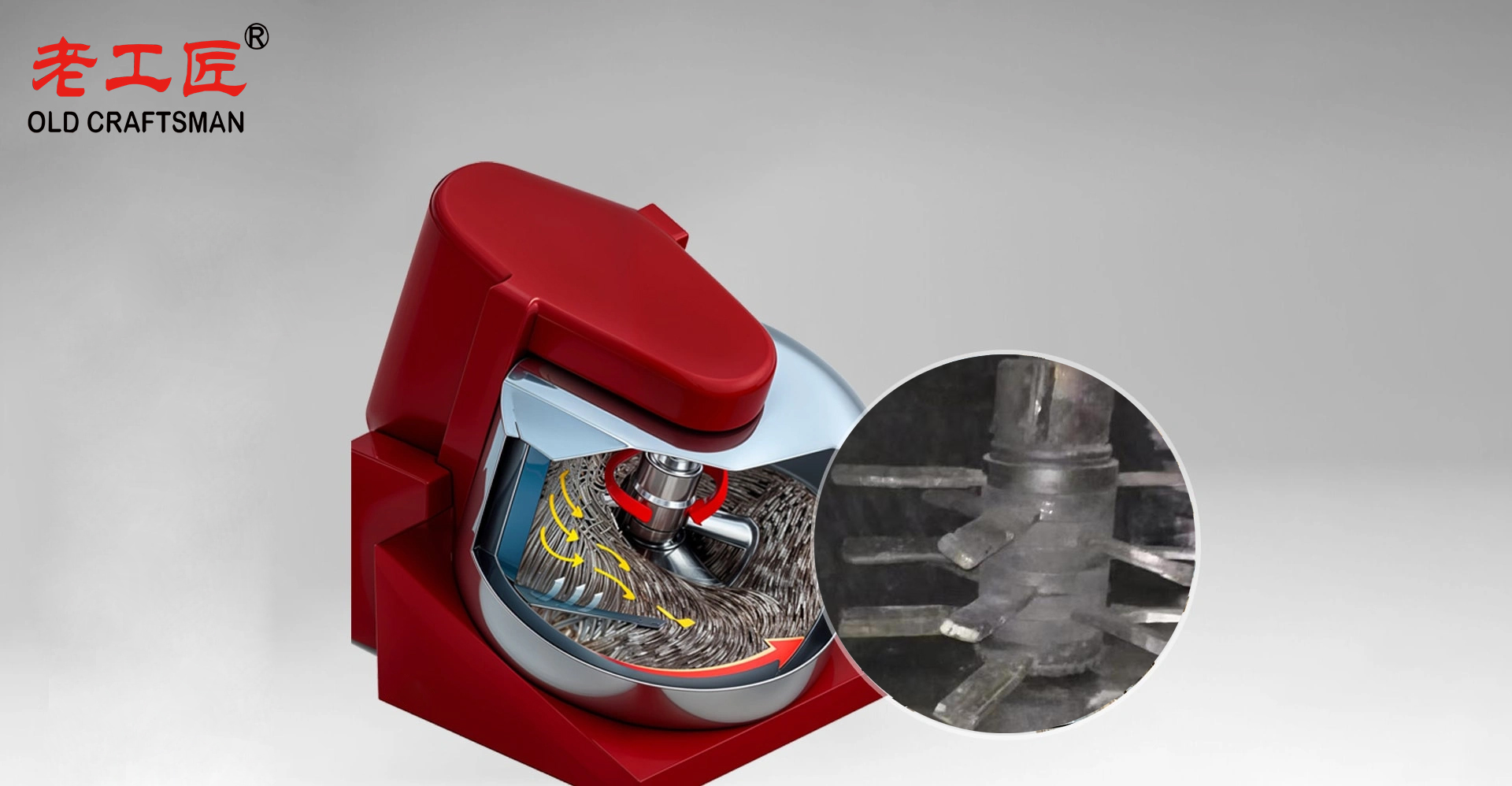

1. The Hostile Environment of a Heavy Duty Mixer

Heavy-duty intensive mixers (like those used in the production of explosives, ceramics, composites, and advanced batteries) are not gently stirring ingredients. They are subjecting their components to:

- High Abrasion: Materials like silica, minerals, metal powders, and carbon fibers are highly abrasive. They act like sandpaper, constantly grinding away at the mixer blades.

- Significant Impact & Shock Loads: Dense, chunky materials or the process of breaking agglomerates can create substantial impact forces on the blade tips.

- High Torque and Shear Forces: These mixers operate with immense power to knead, shear, and homogenize viscous or paste like materials.

- Corrosive Environments: Some mixed materials can be chemically corrosive, adding another dimension of wear.

2. The Limitations of Traditional Materials

- Tool Steel: While tough, it lacks the hardness to resist abrasive wear. It will dull and lose its edge quickly, changing the mixer’s dynamics and contaminating the batch with worn metal particles.

- Hardened Steel / Stellite: An improvement over tool steel, but still not hard enough for the most demanding applications. They require more frequent re-sharpening or replacement.

3. The Superior Properties of Tungsten Carbide

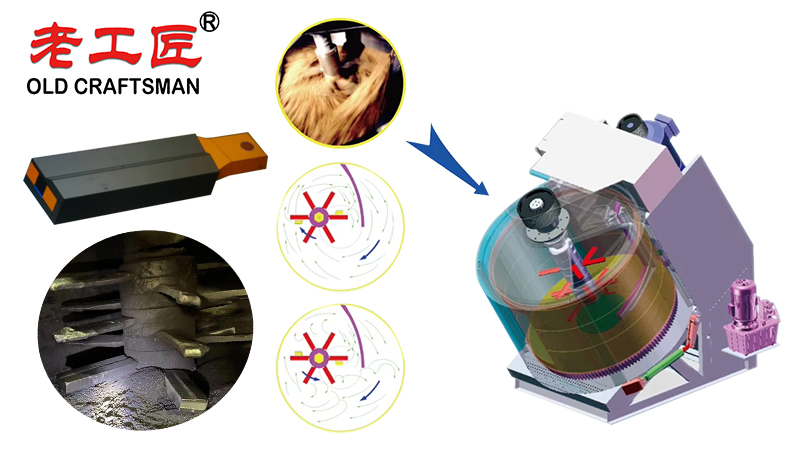

This is where Tungsten Carbide shines. It’s not a pure metal but a ceramic-metallic composite (a cermet), typically consisting of tungsten carbide particles bonded together with a cobalt (or nickel) binder.

| Property | Why It Matters for Mixer Blades | Result |

|---|---|---|

| Extreme Hardness (~9 on Mohs scale, Vickers hardness up to 1600 HV) | Resists cutting, scratching, and deformation caused by abrasive particles. It is significantly harder than hardened steel. | Massively Reduced Wear: The blade profile and sharp edge are maintained for vastly longer periods. |

| Exceptional Wear Resistance | This is the direct benefit of its hardness. It withstands the “sanding” action of abrasive materials far better than any steel. | Longer Service Life: Blades can last 10 to 25 times longer than steel blades, drastically reducing replacement frequency. |

| High Compressive Strength | Can withstand the immense pressure of being forced through dense, viscous materials without deforming. | Maintained Clearance: Critical tolerances between the blade tip and the mixer wall are preserved, ensuring consistent shear and mixing action. |

| Good Toughness | The cobalt binder provides a degree of shock resistance, preventing the brittle carbide from chipping or cracking under impact loads. | Reliability: Withstands the “pounding” from chunks of material, making it suitable for intensive applications. |

The Tangible Benefits: Why Companies Insist on Tungsten Carbide

Switching to Tungsten Carbide blades transforms the operational and economic outlook of a mixing process.

- Dramatically Reduced Downtime: The single biggest cost in industrial manufacturing is often unscheduled downtime. Replacing worn steel blades is a frequent, time consuming, and labor intensive task. With blades that last for months or years instead of weeks, production uptime soars.

- Consistent Product Quality: As a steel blade wears, the geometry of the mixing action changes. This alters the shear rate, heat generation, and homogenization process, leading to batch-to-batch inconsistency. Tungsten Carbide blades maintain their precise geometry, ensuring that every batch is mixed identically.

- Lower Total Cost of Ownership (TCO): While the initial purchase price of a Tungsten Carbide blade is 3-5x higher than a steel blade, the fact that it lasts 10-25x longer makes it far cheaper in the long run. You save on:

- Cost of replacement blades.

- Labor for change outs.

- Lost production during downtime.

- Disposal costs for worn blades.

- Reduced Contamination: Worn steel blades shed fine metallic particles into the product mix. This is unacceptable in industries like pharmaceuticals, lithium-ion batteries, or high performance composites. Tungsten Carbide’s wear resistance minimizes this metallic contamination, protecting product purity.

Common Applications: Where You’ll Find Them

Tungsten Carbide blades are not for mixing cake batter. They are essential in industries where the materials are exceptionally tough on equipment:

- Energetics & Explosives: Mixing highly abrasive compounds like RDX, HMX, and ammonium nitrate.

- Advanced Ceramics: Processing slurries containing alumina, zirconia, and silicon carbide.

- Composite Materials: Kneading carbon fiber, glass fiber, and resin mixtures.

- Lithium-Ion Battery Electrode Slurry: Mixing abrasive cathode materials (like NMC, LFP) with conductive carbons and binders.

- Pharmaceuticals: For high-shear mixing of abrasive active pharmaceutical ingredients (APIs).

- Putties & Sealants: Mixing filled, viscous materials that require high torque.

High performance intensive mixers equipped with wear resistant blades are critical in processing metal matrix composites (MMCs) reinforced with aluminum oxide particles for demanding industrial applications. These blades, typically manufactured from heat treated stainless steel or advanced carbon steel grades, must maintain sharp cutting edges and exceptional mechanical properties even under high temperature operation. The naturally occurring high hardness and compressive strength of aluminum oxide particles, combined with the excellent tensile strength and relatively low coefficient of thermal expansion of the metal matrix, enable the composite raw material to withstand severe abrasive wear at elevated temperatures while preserving dimensional stability from room temperature up to several hundred degrees Celsius. Advanced manufacturing processes and precise heat treating further enhance the overall physical properties, ensuring long service life of the cutting tools in high shear mixing environments.

Conclusion

Calling Tungsten Carbide blades “essential” is not an overstatement. For heavy duty intensive mixers, they are a critical engineering solution to an extreme wear problem. By providing unmatched durability and consistency, they move from being a simple component to a strategic asset that safeguards product quality, maximizes production efficiency, and minimizes operating costs. The initial investment is quickly justified by the profound long term benefits.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding