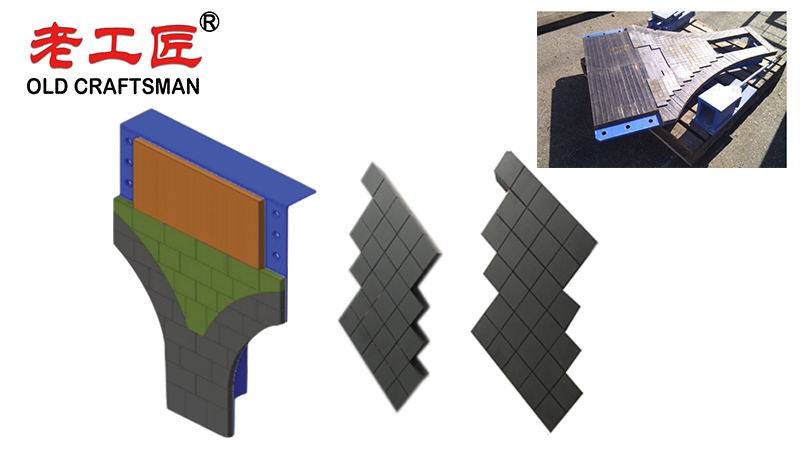

Tungsten carbide cheek plates are essential for High Pressure Grinding Rolls (HPGR) performance due to their exceptional hardness, wear resistance, and durability under extreme operating conditions. Here’s why they are critical:

1. Superior Wear Resistance

- HPGRs operate under high pressures (50-300 MPa), causing significant abrasion from hard, abrasive ores.

- Tungsten carbide (WC) has extreme hardness (~90 HRA), far exceeding steel or other alloys, drastically reducing wear and extending service life.

2. Enhanced Durability Under High Stress

- The compressive strength of tungsten carbide (up to 6,000 MPa) allows it to withstand the intense forces in HPGRs without cracking or deforming.

- Unlike steel, which can fatigue over time, WC maintains structural integrity, reducing unplanned downtime.

3. Improved Grinding Efficiency & Consistency

- Worn cheek plates lead to uneven particle size distribution and reduced throughput.

- Tungsten carbide’s wear resistance ensures consistent gap spacing between rolls, maintaining optimal grinding performance and product quality.

4. Reduced Maintenance & Downtime

- Longer lifespan than steel cheek plates means fewer replacements, lowering operational costs and increasing machine availability.

- Minimizes the need for frequent shutdowns, improving overall HPGR productivity.

5. Corrosion & Heat Resistance

- Resists oxidation and chemical degradation from moist or corrosive ores.

- Maintains performance even at elevated temperatures generated during grinding.

6. Cost-Effectiveness Over Time

- Although initial costs are higher than steel, the extended service life of tungsten carbide cheek plates results in lower total cost of ownership (TCO).

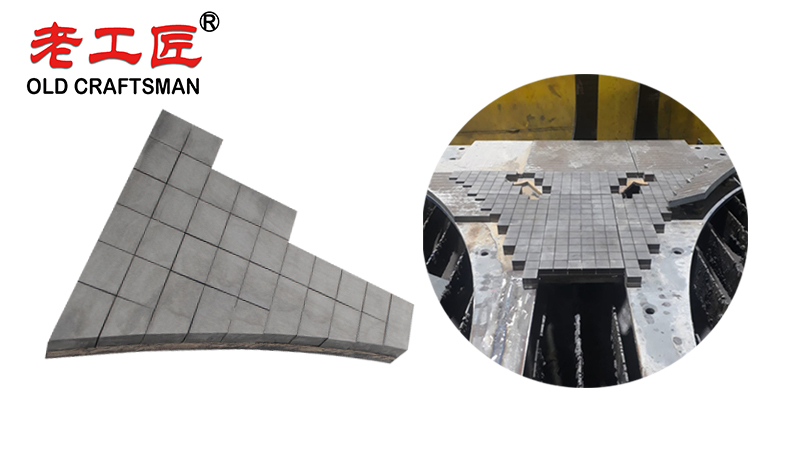

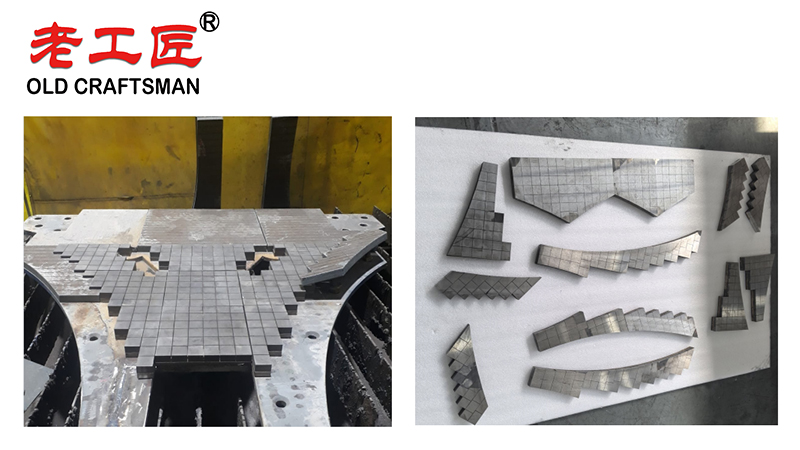

High-pressure grinding rolls (HPGR) cheek plates are critical wear parts exposed to extreme high temperature abrasive wear conditions during operation. These components experience multiple types of wear simultaneously, including severe three-body abrasion, gouging, and impact under cyclic loading, which accelerates the removal of material from the surface. To extend service life, reduce wear rates, and lower long-term operating costs, cheek plates are manufactured from highly abrasion resistant and wear resistant materials with optimized mechanical properties, such as hardness, toughness, and a low coefficient of friction.

Advanced chromium molybdenum white cast irons, tungsten carbide composites, or overlay welded plates are commonly selected for their superior resistance to both high temperature oxidation and aggressive abrasive environments. Proper material selection, combined with regular preventative maintenance and monitoring through asset management software, significantly minimizes unplanned downtime and reduces overall wear and tear on this expensive piece of equipment.

Standardized test methods (e.g., ASTM G65 dry sand/rubber wheel, high-stress abrasion tests, and elevated temperature pin-on-disk tests) are used to compare the performance of different wear resistant materials and predict real-world behavior. By choosing the optimal cheek plate design and material, operators can dramatically slow material loss, improve energy efficiency, and achieve substantial cost reductions over the equipment’s lifespan.

Conclusion

Tungsten carbide cheek plates are indispensable for HPGRs because they maximize wear life, maintain grinding efficiency, reduce maintenance, and improve operational reliability key factors in high tonnage mineral processing operations.

Tungsten carbide HPGR cheek plates represent a significant advancement in wear protection technology, offering mining and processing operations an effective solution for extending equipment life while reducing total operating costs.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could production tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized tungsten carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding