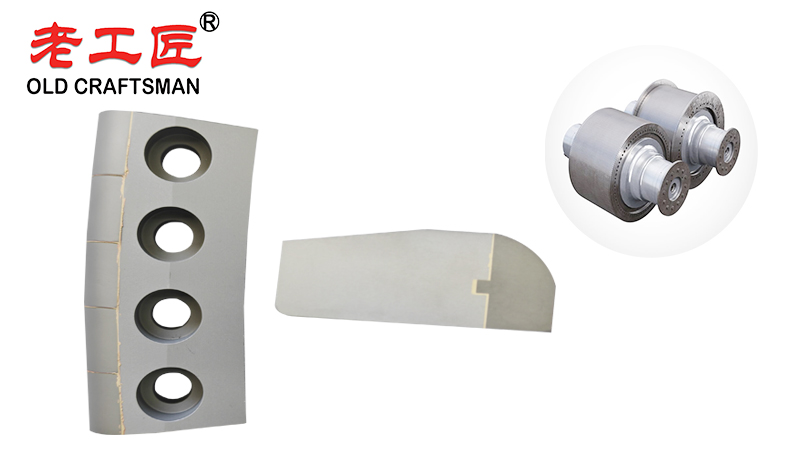

Tungsten carbide edge blocks are revolutionizing High Pressure Grinding Rolls (HPGR) performance due to their exceptional hardness, wear resistance, and durability. Here’s why they are transforming HPGR operations:

1. Unmatched Wear Resistance

Tungsten carbide (WC) is one of the hardest materials available, second only to diamond. This makes edge blocks highly resistant to abrasion, significantly extending their lifespan compared to traditional steel or alloy alternatives.

2. Increased Operational Efficiency

- Longer Service Life: Reduces downtime for replacements, boosting productivity.

- Consistent Grinding Performance: Maintains optimal pressure and gap control over time, ensuring uniform particle size reduction.

3. Cost Savings

- Fewer replacements mean lower maintenance costs.

- Reduced energy consumption due to sustained efficiency.

4. Enhanced Durability in Harsh Conditions

- Resists extreme pressures (up to 300 MPa) and abrasive ores (e.g., iron, gold, diamond).

- Performs well in high temperature and corrosive environments.

5. Improved Grinding Performance

- Maintains sharp edges longer, ensuring efficient compression grinding.

- Reduces slippage and improves throughput.

6. Sustainability Benefits

- Longer lifespan means fewer discarded parts, reducing waste.

- Energy-efficient grinding lowers carbon footprint.

Applications in Mining & Cement Industries

- Mining: Ideal for hard ores (copper, gold, platinum).

- Cement: Enhances clinker grinding efficiency.

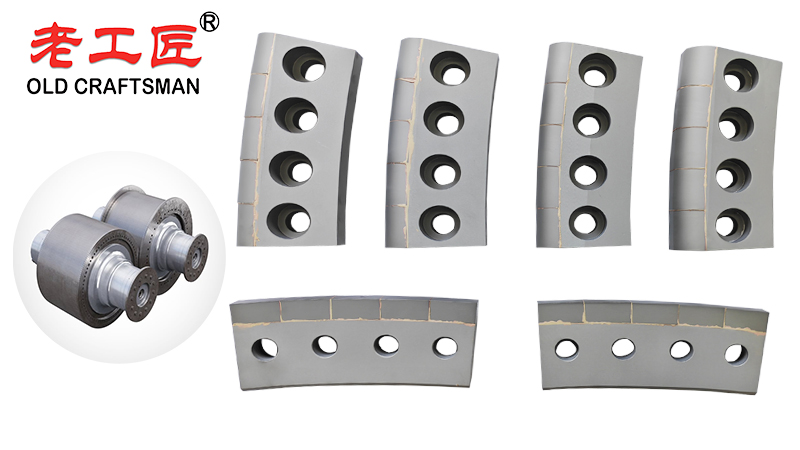

High-pressure grinding rolls (HPGR) rely on advanced wear parts, such as edge blocks, to withstand extreme conditions in grinding operations on abrasive raw materials. These high performing edge blocks, manufactured through a specialized high temperature process, incorporate premium abrasive grains like aluminum oxide combined with superior wear resistant materials for exceptional high strength and durability. Leading wheel manufacturers and abrasive products suppliers utilize these components in grinding machines to combat abrasive wear under high pressures, delivering high-quality surface finishes while significantly improving productivity in demanding grinding processes.

Our company is committed to problem solving and enhancing customer experience by offering a wide range of innovative wear parts, including high temperature resistant HPGR edge blocks designed to withstand extreme conditions in high pressure grinding rolls. Through continuous improvement in our high strength grinding wheel manufacturing process which incorporates advanced techniques to remove material from tough substrates like stainless steel we eliminate waste in production processes and business processes alike. This focus on operational efficiency not only delivers cost savings by reducing costs but also creates superior value for the customer, boosting overall customer satisfaction.

Conclusion

Tungsten carbide edge blocks are setting new standards in HPGR technology by delivering superior wear resistance, cost efficiency, and operational reliability. Their adoption is rapidly growing in mining and cement industries, making them a game changer for high-pressure grinding applications.

A successful tungsten carbide HPGR wear edge block solution balances material science, engineering design, and operational practicality. Prioritize high impact zones with tunsgten carbide, optimize installation for quick maintenance, and partner with experienced suppliers to ensure longevity in harsh mining environments.

Our advanced manufacturing process makes HPGR carbide edge blocks and related wear parts. It is designed for top performance in high temperature and high pressure grinding rolls (HPGR) applications. Through rigorous continuous improvement and targeted process improvement across all business processes from premium raw materials sourcing to precision grinding wheel finishing we consistently improve operational efficiency, improve productivity, and proactively measure operational efficiency with real-time metrics. This careful, long term method provides high quality, affordable carbide solutions. These solutions lower costs, create significant savings, and ensure great long term performance for grinding operations around the world.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding