Tungsten carbide (WC) is widely regarded as the ideal material for High Pressure Grinding Roll (HPGR) flanges in mining applications due to its exceptional combination of hardness, wear resistance, and toughness. Here’s why:

1. Extreme Hardness & Wear Resistance

- Tungsten carbide has a Vickers hardness of ~1,500–2,400 HV, making it one of the hardest materials available, second only to diamond.

- In HPGR applications, flanges endure abrasive wear from ore particles. WC’s hardness ensures minimal material loss, extending service life significantly compared to steel or other alloys.

2. High Compressive Strength

- HPGRs operate under extremely high pressures (50–300 MPa) to crush ore.

- Tungsten carbide has exceptional compressive strength (up to 6,000 MPa), preventing deformation under load.

3. Superior Fracture Toughness

- Unlike brittle ceramics, WC-Co (tungsten carbide with a cobalt binder) offers high fracture toughness (8–12 MPa·m½).

- This prevents catastrophic cracking under cyclic loading, a common failure mode in HPGR operations.

4. Corrosion & Heat Resistance

- WC is chemically inert, resisting corrosion from acidic or wet ore processing environments.

- It maintains strength at elevated temperatures (up to 500–600°C), crucial in high-friction HPGR applications.

5. Cost Efficiency Over Long-Term Use

- While initial costs are higher than steel, WC flanges last 5–10 times longer, reducing downtime and replacement frequency.

- Lower maintenance costs and increased productivity justify the investment.

Comparison with Alternatives

| Material | Hardness (HV) | Wear Resistance | Toughness | Cost Efficiency |

|---|---|---|---|---|

| Tungsten Carbide | 1,500–2,400 | Excellent | High | Best (long-term) |

| Hardened Steel | 600–900 | Moderate | High | Moderate (frequent replacement) |

| Ceramics (Al₂O₃, ZrO₂) | 1,200–1,800 | High | Low (brittle) | Poor (risk of cracking) |

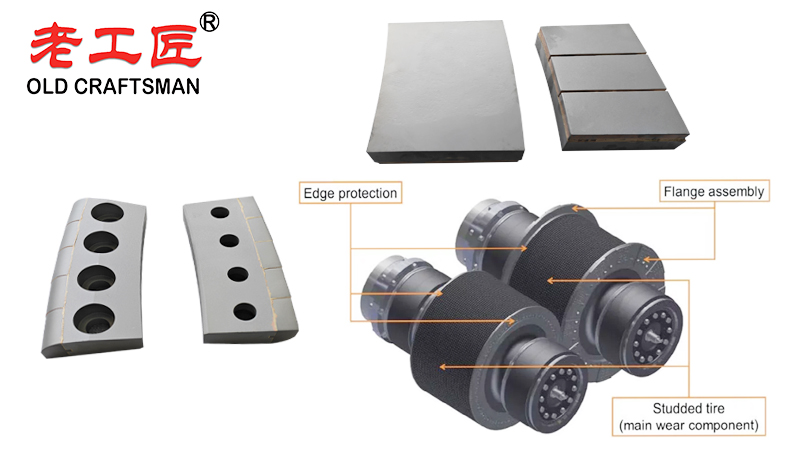

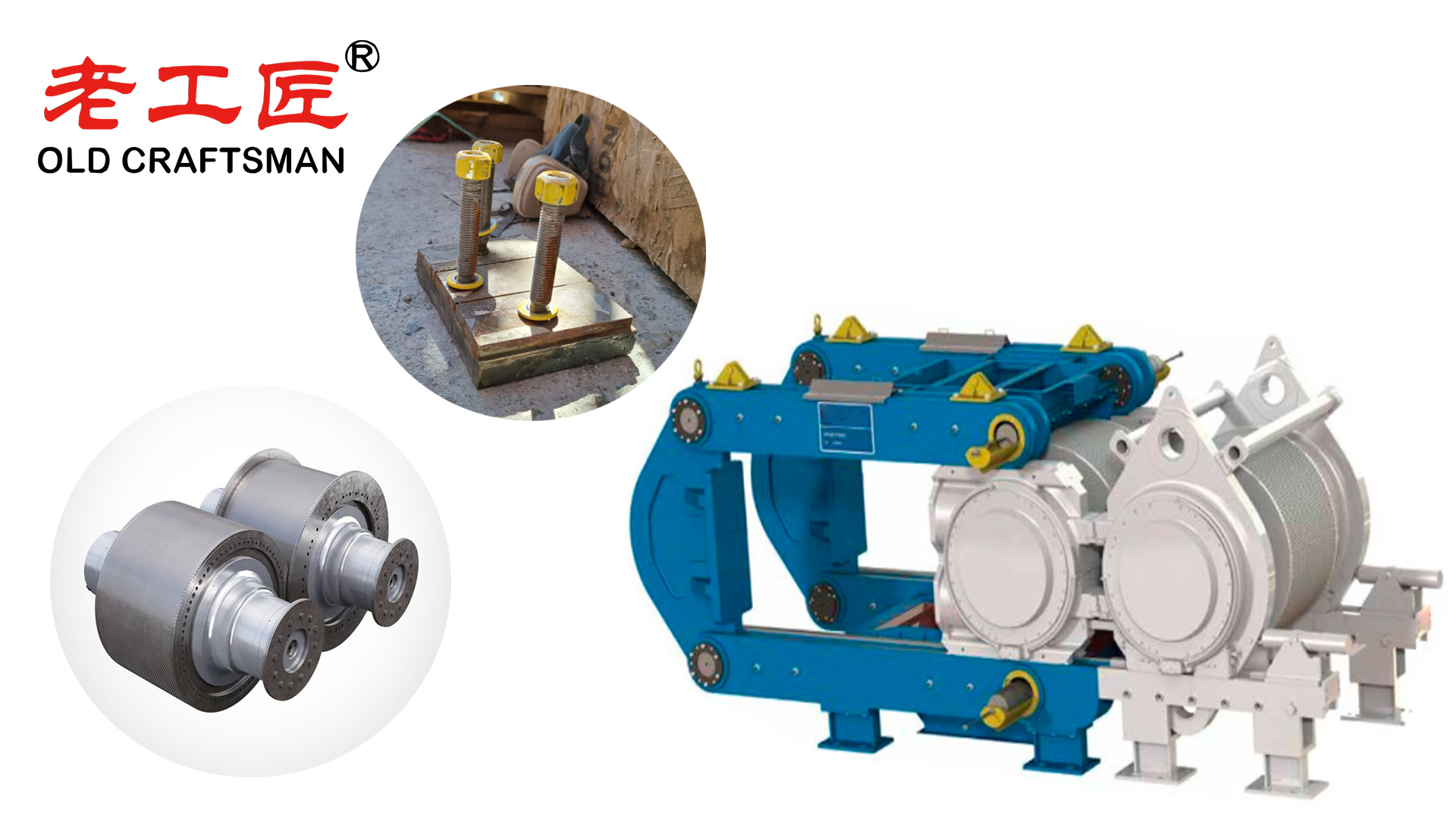

High-Performance Grinding Rolls (HPGR) equipped with carbide flanges are widely used in the mining and cement industries due to their exceptional abrasion resistant and corrosion resistant properties under high temperatures. These wear parts experience significant losses primarily from abrasive and adhesive wear mechanisms, which are strongly influenced by the coefficient of friction between the carbide studs and the processed material. To evaluate service life and optimize the manufacturing process, various test methods such as ASTM G65 dry sand/rubber wheel tests, pin-on-disk tests under applying load and elevated temperature conditions, and field trials are employed. Key material properties including melting point (>2600 °C for tungsten carbide), mechanical properties (high compressive strength, moderate tensile strength), and plane strain fracture toughness (typically 10–20 MPa·m¹/², as detailed in Wikipedia and technical literature) determine the ability of the carbide to resist material loss and catastrophic failure. During the production process, powder metallurgy techniques are used to produce dense, high quality carbide components that maintain performance across a wide range of operating conditions, making HPGR rolls an indispensable cutting tool-like component in high pressure comminution circuits.

Conclusion

For HPGR flanges, tungsten carbide is unmatched in durability, wear resistance, and operational efficiency, making it the preferred choice in modern mining operations. Its ability to withstand extreme pressure and abrasion ensures longer lifespan and lower total cost of ownership compared to steel or ceramic alternatives.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding