Tungsten Carbide (WC) is the material of choice for intensive mixer blades because it offers an unparalleled combination of extreme hardness, exceptional wear resistance, and high compressive strength. These properties directly combat the primary causes of failure in this demanding application.

Here’s a detailed breakdown of why it’s the superior material:

1. Exceptional Wear Resistance (Abrasion)

- The Problem: Intensive mixers process abrasive materials like ceramics, metal powders, minerals, and composites. These act like sandpaper, constantly grinding away at the blade surfaces.

- The Solution: Tungsten carbide is one of the hardest materials on earth, second only to diamonds and boron nitride in practical applications. Its hardness (~70-90 HRC, or ~9 on the Mohs scale) means it resists material removal far better than tool steel or other alloys. This drastically reduces the rate of wear.

2. High Compressive Strength

- The Problem: The blades must withstand enormous forces as they push, shear, and knead dense, often viscous materials. This can cause deformation (bending or denting) in weaker materials.

- The Solution: Tungsten carbide has a very high compressive strength (over 500,000 psi), meaning it can bear immense loads without deforming. This maintains the precise geometry and clearance of the blade, which is critical for mixing efficiency.

3. Superior Erosion Resistance

- The Problem: In some mixing applications, a slurry of liquid and abrasive particles can cause erosive wear, which is a combination of mechanical and chemical attack.

- The Solution: The chemical inertness and dense microstructure of tungsten carbide make it highly resistant to erosion, ensuring a longer lifespan even in wet or corrosive environments.

The Result: Dramatically Extended Service Life

This is the single most important benefit. While a standard steel blade might need replacement every few months (or even weeks in severe applications), a tungsten carbide clad blade can last for several years.

- Reduced Downtime: Fewer blade changes mean less production stoppage for maintenance.

- Lower Long-Term Cost: Although the initial investment in tungsten carbide components is significantly higher, the dramatically extended lifespan and reduced maintenance labor lead to a much lower total cost of ownership over time.

- Consistent Mixing Performance: As the blades wear, the mixing efficiency and product consistency can change. Tungsten carbide’s resistance to wear ensures the mixing action remains consistent throughout its long life, leading to higher quality end products.

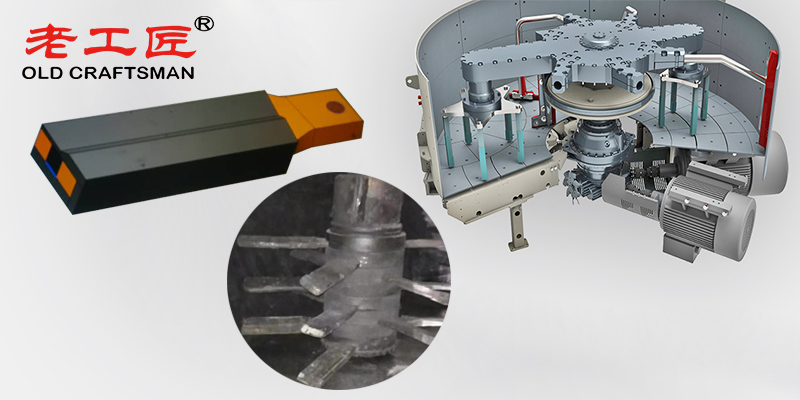

How It’s Applied: Cladding vs. Solid

It’s important to note that mixer blades are rarely made from solid tungsten carbide due to its cost and brittleness. Instead, the superior solution is often tungsten carbide cladding:

- Base Material: The blade itself is manufactured from a tough, shock-resistant steel alloy (like 4140 or 4340 steel). This provides the structural integrity and ability to absorb impacts without cracking.

- Cladding Process: A thick layer of tungsten carbide is applied to the high wear areas of the blade (leading edges, tips, and surfaces facing the material flow) using a process like HVOF (High Velocity Oxygen Fuel) thermal spraying. This process creates an extremely hard, dense, and well-bonded coating.

- The Best of Both Worlds: This combination gives the blade the surface hardness of tungsten carbide to resist wear, backed by the toughness and flexibility of steel to withstand operational stresses.

Comparison to Other Materials

| Material | Key Property | Drawback in Intensive Mixers |

|---|---|---|

| Tool Steel (e.g., AR400) | Tough, Impact Resistant | Wears out too quickly, requires frequent replacement |

| Stellite Alloys | Good wear & corrosion resistance | Softer and less wear resistant than Tungsten Carbide |

| Ceramics | Extremely Hard | Too brittle, high risk of chipping or catastrophic failure |

| Solid Tungsten Carbide | Maximum Hardness/Wear Resistance | Prohibitively expensive and brittle for a large part |

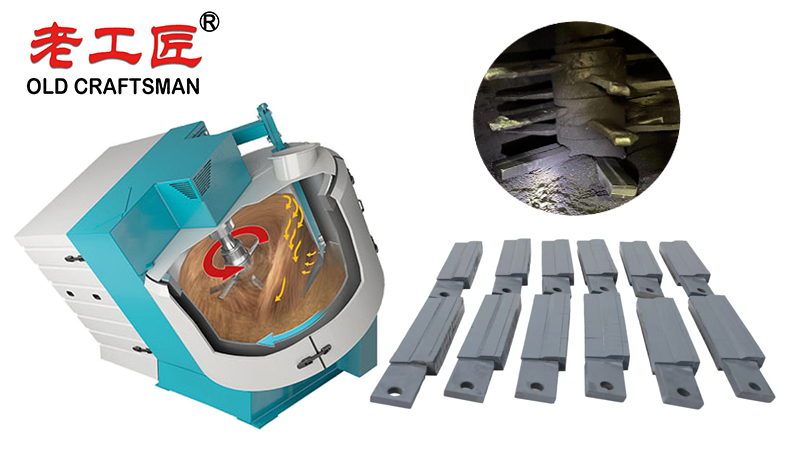

The production process of blades for carbide intensive mixers demands materials with exceptional performance under extreme conditions. These blades must withstand high temperatures, intense abrasion, and corrosive environments typically found in industries like refractory, ceramics, and advanced materials processing. To achieve superior heat resistance, abrasion resistance, and corrosion resistance, manufacturers predominantly use cemented carbides (tungsten carbide cobalt bonded composites) or advanced high strength alloy steels containing high performance alloying elements. While stainless steel and carbon steel are sometimes used as base materials, critical components are often coated or fully made from heat treated cemented carbides to ensure long service life. The manufacturing process includes precision forming, sintering, grinding of cut edges, and specialized heat treatment to optimize hardness and toughness across a wide range of operating conditions. These high quality, abrasion resistant blades deliver outstanding durability and reliability, making them a cost effective solution compared to frequent replacement of conventional high speed steel or untreated alloy tools.

Conclusion

Tungsten carbide is chosen because it directly solves the most critical problem in intensive mixing: severe wear. By providing extreme hardness and wear resistance, it ensures operational reliability, product consistency, and the lowest possible long term cost, making it the undisputed material of choice for the most demanding mixing applications.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding