Using ZZ Old Craftsman’s tungsten carbide wear liners can significantly enhance the efficiency and durability of High Pressure Grinding Rolls (HPGR) in several ways. Here’s why:

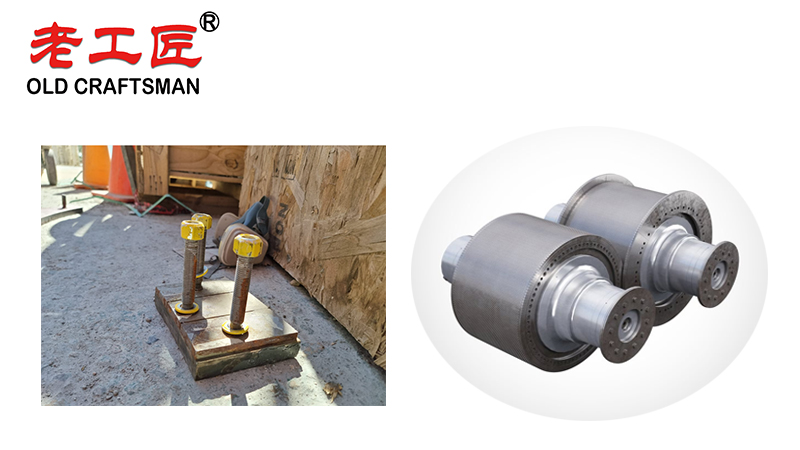

1. Superior Wear Resistance

- Tungsten carbide is one of the hardest materials available, offering exceptional resistance to abrasion and wear.

- This extends the lifespan of HPGR liners, reducing downtime for replacements and maintenance.

2. Higher Crushing Efficiency

- The hardness and toughness of tungsten carbide ensure consistent grinding performance over time.

- Maintains optimal gap size between rolls for longer, ensuring uniform particle size reduction.

3. Reduced Energy Consumption

- Efficient wear resistance means less friction and energy loss during operation.

- HPGRs with tungsten carbide liners can operate at lower power inputs while maintaining high throughput.

4. Lower Operational Costs

- Longer liner lifespan means fewer replacements, reducing material and labor costs.

- Minimized maintenance interruptions lead to higher overall equipment effectiveness (OEE).

5. Enhanced Product Quality

- Consistent liner wear ensures stable grinding conditions, improving product fineness and uniformity.

- Reduces overgrinding, which can be critical in mineral processing applications.

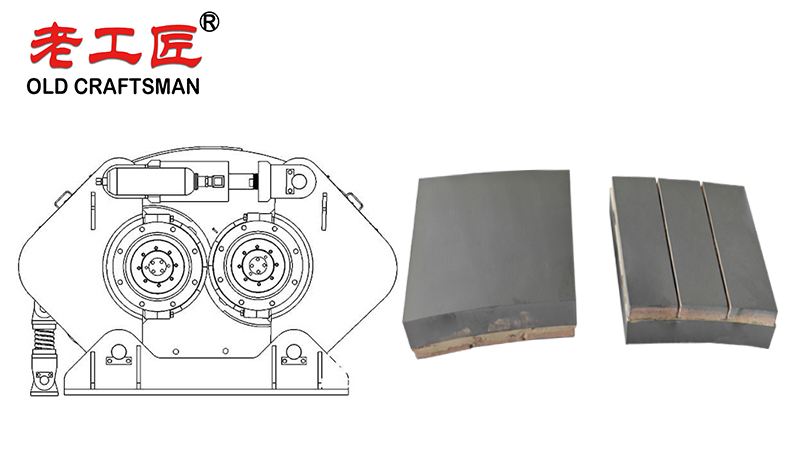

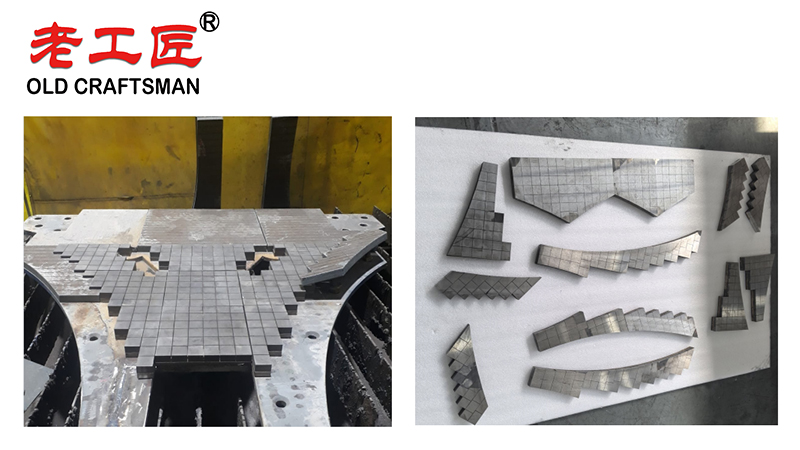

6. Customizable Designs for Optimal Performance

- ZZ Old Craftsman offers tailored tungsten carbide liners designed for specific HPGR models and applications.

- Custom patterns and geometries can improve material flow and crushing efficiency.

Conclusion

By using ZZ Old Craftsman’s tungsten carbide wear liners, HPGRs achieve:

✔ Longer service life

✔ Higher energy efficiency

✔ Lower maintenance costs

✔ More consistent grinding performance

This makes them an excellent choice for mining, cement, and mineral processing industries where HPGR efficiency is critical.

High Pressure Grinding Rolls (HPGR) equipped with carbide wear liners offer a cost effective, long term solution for power plants relying on fossil fuels and natural gas, which consume massive amounts of energy. These resistant materials excel in high temperature environments and combat abrasive wear effectively, preserving the mechanical properties of the equipment over extended periods. By minimizing energy waste and reducing downtime, HPGR carbide wear liners help save energy and lower energy bills significantly. Unlike electric vehicles or home energy systems focused on hot water and water heating efficiency, this industrial approach delivers substantial savings on power generation costs, ultimately helping operators save money in demanding operational conditions.

Tungsten carbide wear liners deliver exceptional abrasion resistance and outstanding performance in high temperature environments, making them the ideal wear resistant material for power plants facing severe abrasive wear. By significantly extending equipment service life and reducing unplanned downtime, these high performance liners minimize the need for frequent replacements and maintenance, directly lowering energy consumption. This results in substantial long term cost savings on energy bills for power plants, while simultaneously contributing to overall energy saving goals much like upgrading to efficient light bulbs, optimizing water heating systems, or improving heating and cooling efficiency. Choosing tungsten carbide wear liners allows industrial facilities to resist material loss effectively, save energy, and achieve impressive reductions in both operational costs and total energy usage, supporting a more sustainable and profitable future alongside renewable energy initiatives.

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding