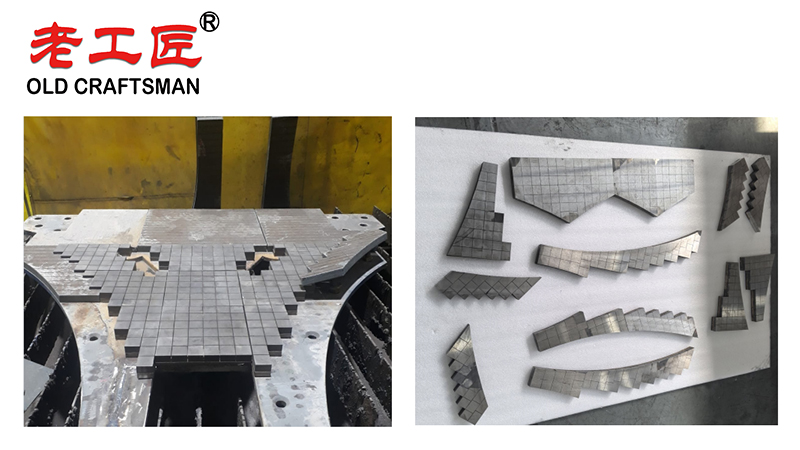

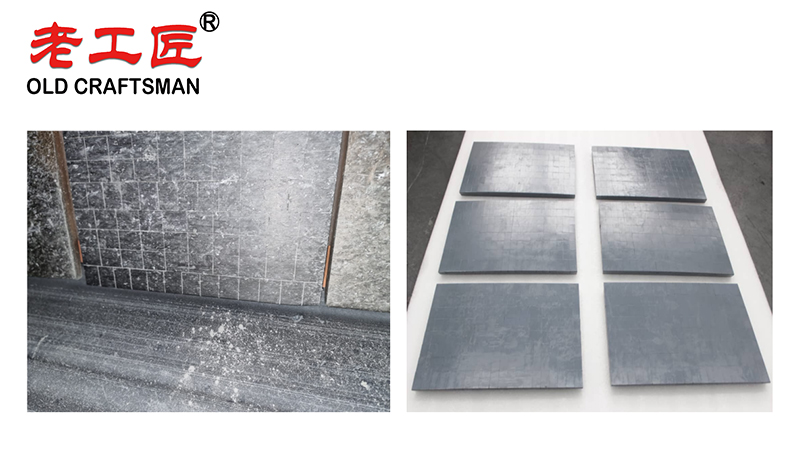

Carbide wear Plates is the super extreme in wear resistant liners and is designed for applications that experience severe abrasion, where a standard wear plate is ineffective. Carbide wear liner is available with Tungsten Carbide tiles, in a range of thickness up to 30mm, vacuum brazed to a mild steel backing plate. We are good at customized design, from the shape and carbide grade of the product. If you have a new requirement or want to upgrade your present material to get a much longer life, please contact us.

Base Material of the Wear Plates

The standard base material is mild steel plate of varying thickness, ensuring the finished parts are readily weldable.

Carbide Tiles Properties, we have many grades for different usage, and we can design new grades according to different customers’ requirements to meet their on site needs. Below are some standard grades we are using, and the brazing strength is higher than 220MPa.

| Grade | Density g/cm3 | Hardness HV3(HRA) | Strength MPa |

| YG6 | 14.85-15.05 | 91.5 | 2200 |

| YG8 | 14.65-14.85 | 90 | 2600 |

| YG8C | 14.55-14.75 | 88.5 | 2800 |

| YL10.2 | 14.40-14.55 | 91.5 | 3200 |

| YG11 | 14.30-14.50 | 88.5 | 2700 |

| YG11C | 14.20-14.40 | 87 | 2800 |

| YG15 | 13.95-14.15 | 88 | 3200 |

Welding of the Wear Plates

Welding to the base plate is possible, but not recommended, except for stud welding (AS 1554.2), as this may compromise the bond between the base material and tiles.

Benefits of Our Vacuum Brazed Wear Plates

- Vacuum brazed bond exceeds typical bond strength for rubber or direct bonded ceramics.

- Mild steel base plate can be easily stud welded.

- Extremely hard liners for extremely abrasive conditions.

- Personalized customization can meet the on site use of different customers

Applications of the Wear Plates

Applications involving severe sliding abrasion and medium impact, such as

- Chutes

- Deflector chutes

- Ore Handling Systems

- Liner Plates

- Hoppers

- Conveyor skirts

- Conveyor drag plates

- HPGR feed cheek plates

- HPGR flange

Welcome to contact us for the customized design!

“Zhuzhou Old Craftsman Precision Alloy Co., Ltd. could make tungsten carbide wear parts and make your equipment use life is tens of times longer than before! We specialize in providing customized carbide wear products solutions to meet the demanding requirements of industries such as aerospace, automotive, mining, and precision machining.”

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding