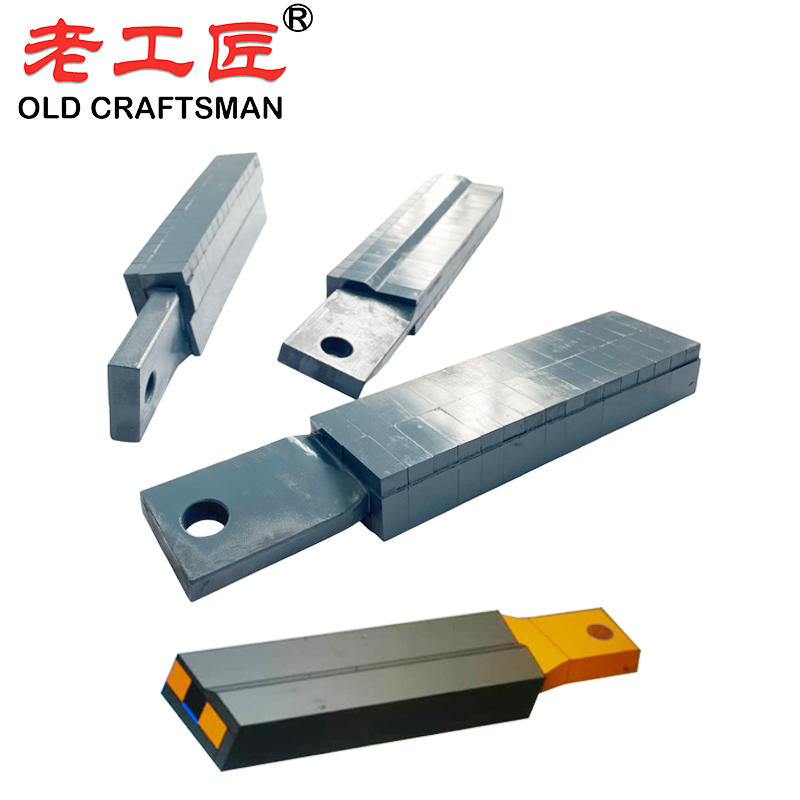

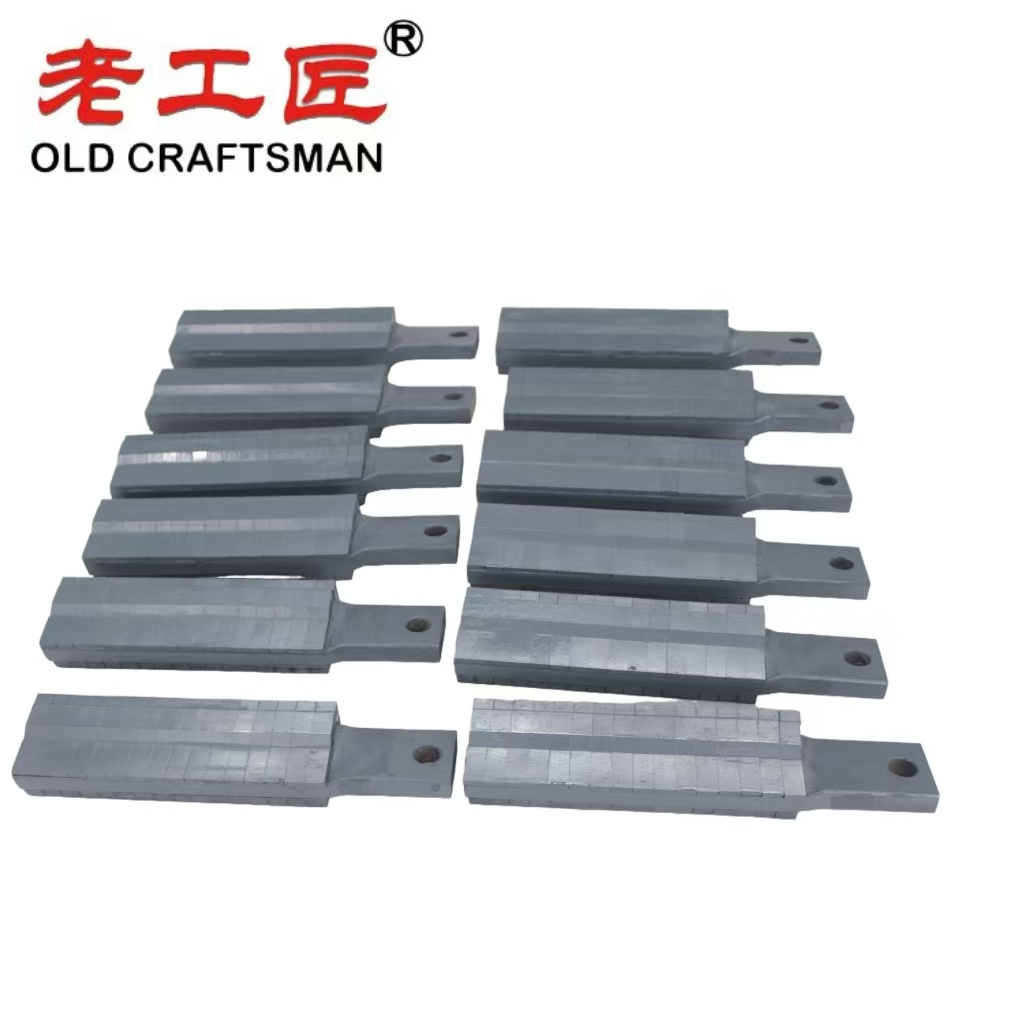

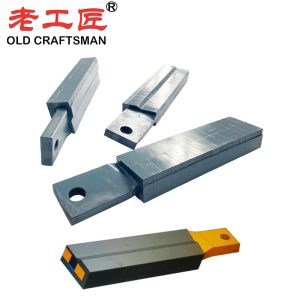

I. The carbide brazed intensive mixers blade produced by ZZ OLD CRAFTSMAN, perfectly combines the advantages of cemented carbide and steel

Intensive mixer blades prepare refractory mortar by blending hexamine, graphite, resin powder, and highly abrasive alumina oxide or sintered magnesite. These materials rapidly wear standard blades, making wear-resistant construction critical.

Common market options include stainless steel, alloy steel, and full carbide. Alloy steel offers toughness but poor abrasion resistance; full carbide excels in wear but lacks impact strength.

ZZ Old Craftsman’s carbide-brazed intensive mixer blades perfectly combine cemented carbide’s superior hardness and high-temperature stability with steel’s toughness and mechanical strength. Through vacuum brazing, we achieve a strong, crack-free bond that maximizes both materials’ advantages.

The result: blades that endure extreme abrasion, high stress, and thermal loads—delivering longer life, reduced breakage risk, and consistent mixing performance in demanding refractory production.

For more details, please check on the page: https://www.zzcraftsman.com/leading-technology-carbide-brazed-mixer-blades-help-innovation-in-refractory-production/

II. Features of the Intensive Mixers Blade:

*100% Chinese famous brand virgin material, HIP sintering

*Carbide grades are chosen according to onsite usage

*Vacuum Brazing, internal pressure released well

*ISO 9001 production standard, ERP, and MES control the whole production process

*Comprehensive Quality Inspection throughout the whole production

III. Features of the vacuum brazing:

1. Brazing strength: Vacuum brazing can generate stronger brazing strength, which can be over 200Mpa

2. Large-area brazing: Vacuum brazing is more suitable for large-area brazing, and it is not easy to cause alloy cracking

3. Less false brazing: Vacuum brazing is not prone to false brazing. Because the temperature in the furnace is uniform, and the flux is easy to cover the entire brazing area.

4. Eco-friendly: Vacuum brazing is more environmentally friendly and produces less pollution.

IV. Why choose ZZ Old Craftsman’s Intensive Mixers Blade?

*1. Our company’s been doing vacuum brazing for more than 10 years. From the initial experiment to the current mature technique, we’ve accumulated lots of experience.

*2. We communicate closely with customers and help customers adjust the tungsten carbide parameters and upgrade product structure according to the on-site usage so that the use effect of the product reaches the best state.

*3. Our engineers have been in tungsten carbide manufacture for more than 30 years, thus our control of alloys is very precise. At the same time, our company is equipped with complete testing equipment, starting from the testing of carbide powder, testing of press blanks, and testing of finished products after sintering, to ensure that the performance of each batch of products is qualified and stable.

*4. We have a complete production line, from ball milling — pressing — sintering — finishing — brazing — post-processing, to control the quality of products from the source.

We supply such as:

- Intensive Mixers Blade

- Mixing Blade

- Rotor Tool

- Mixer Wearing Parts

- Beater

- Knifelike

- Mixer Bottom Beater

- Concrete Mixer Blades

- Intensive Mixing Blades

V. Application:

Intensive mixers blade is widely used in industrial production and are mainly used for mixing, stirring, and grinding various raw materials and finished products. Here are some of the main uses for intensive mixers blade:

Refractory production: Intensive mixers blade is widely used in the production process of refractory materials to mix various raw materials, such as alumina, aluminum silicate, silicon carbide, etc., as well as additives and binders to ensure the performance and quality of the final product.

Cement production: In the cement production process, the intensive mixers blade is used to mix cement raw materials with auxiliary materials such as limestone and clay evenly to prepare cement slurry that meets standards.

Chemical production: In the chemical industry, intensive mixers blade is used to mix various chemical raw materials, such as liquids, solids, and powders, to prepare various chemical products, such as coatings, pigments, glue, etc.

Food processing: In the food processing industry, intensive mixers blade is used to mix and stir various food raw materials, such as flour, sugar, oil, etc., to prepare various food products, such as bread, biscuits, candies, etc.

VI. FAQ

Q: What are your main products for tungsten carbide brazing?

A: Our advantage products are brazed carbide wear plates, brazed carbide crushing hammerheads, brazed carbide nozzles, brazed carbide scrape blades, brazed liners for refractory brick mold, and any of customized brazed items.

Q: Do you have an OEM&ODM option?

A: Yes, we have. Customized product is our advantage.

Q: What is your MOQ?

A: It depends on the exact product; there usually is no MOQ limitation for standard products.

Q: How long have you been producing this product?

A: We have been doing research and development, and producing carbide brazing products for over 8 years, gaining much successful experience in it.