Project country: Italy

Date: 2021.12

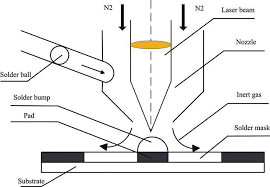

Application: Solder ball laser jetting equipment

Project detail: The carbide brazed nozzle is for solder ball laser jetting equipment operation and use.

Why choose Carbide as material: Carbide is wear-resistant and resistant to high temperature

In the demanding world of industrial processing, where materials are worn down by abrasive slurries, erosive gases, and high-impact particles, the choice of component materials is not merely a matter of preference but of paramount importance for productivity and cost control. Among the critical components in this arena, the nozzle stands as a key interface, directing and controlling the flow of media in applications ranging from waterjet cutting and sandblasting to spray drying and slurry pumping. Here, tungsten carbide brazed nozzles have emerged as the gold standard, offering a remarkable synthesis of extreme hardness and robust structural integrity that outperforms traditional materials by orders of magnitude.

At its core, a tungsten carbide brazed nozzle is a composite masterpiece. It consists of a tungsten carbide (WC) insert or tip, which forms the critical wear-resistant orifice and flow path, permanently joined to a tough steel shank or body via a high-temperature brazing process. This design ingeniously marries the best properties of two distinct materials. Tungsten carbide, a ceramic-metallic composite (cermet) typically made of hard tungsten carbide grains bound with a cobalt or nickel matrix, possesses near-diamond hardness. It exhibits exceptional resistance to abrasive wear, slurry erosion, and, to a significant degree, cavitation. This ensures the nozzle’s internal geometry—the precise diameter and contour that dictate spray pattern, velocity, and efficiency—remains stable over vastly extended periods.

However, pure tungsten carbide is brittle and expensive to form into large, complex shapes. This is where the brazed construction proves its brilliance. The steel body provides the necessary structural strength, ductility, impact resistance, and ease of threading or mounting to standard equipment. The brazing process, which involves heating the assembly with a filler metal that melts at a temperature lower than the base metals, creates a strong, metallurgical bond between the carbide and the steel. A properly executed braze forms a joint that is both mechanically sound and leak-proof, capable of withstanding high operational pressures and cyclic stresses without failure.

The superiority of tungsten carbide brazed nozzles becomes starkly apparent when compared to alternatives. Traditional orifice plates or nozzles made from hardened tool steels or even stainless steels wear rapidly when subjected to abrasive media. Their orifices enlarge and distort, leading to a loss of pressure, flow rate, and process control. This results in inconsistent product quality, higher energy consumption, and frequent, costly downtime for replacements. In contrast, tungsten carbide’s wear life can be 10 to 100 times longer than that of steel. While the initial investment is higher, the total cost of ownership plummets due to dramatically reduced change-out frequency, maintenance labor, and production interruptions.

Ceramic nozzles, often made from alumina or boron carbide, offer excellent abrasion resistance but are inherently more brittle than brazed carbide. They are prone to catastrophic failure from impact or thermal shock. The brazed design, with its resilient steel body, offers superior durability in harsh industrial environments where accidental knocks or pressure surges are possible.

Applications for these rugged components are extensive. In high-pressure waterjet cutting, they focus supersonic streams of water, often laden with abrasive garnet, to slice through metals and composites; here, orifice integrity is critical for cut precision and edge quality. In sandblasting and shot peening, they direct aggressive abrasives to clean or strengthen metal surfaces. The mining and mineral processing industry relies on them for pumping and spraying dense, highly abrasive slurries. Spray drying towers in chemical and food processing use arrays of these nozzles to atomize liquids, where consistent droplet size is vital, and wear would rapidly compromise product uniformity.

In conclusion, tungsten carbide brazed nozzles represent a pinnacle of applied materials engineering. They are not just simple parts but critical performance multipliers. By strategically combining the unparalleled wear resistance of a tungsten carbide liner with the rugged, practical utility of a steel body through a high-integrity braze, they deliver unmatched longevity, reliability, and process stability. In industries where time is money and consistency is king, these unyielding components silently ensure that the heart of the spray system keeps beating strongly, driving efficiency and profitability by standing firm against the relentless forces of wear.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding