Project country: Brazil

Date: 2020.10

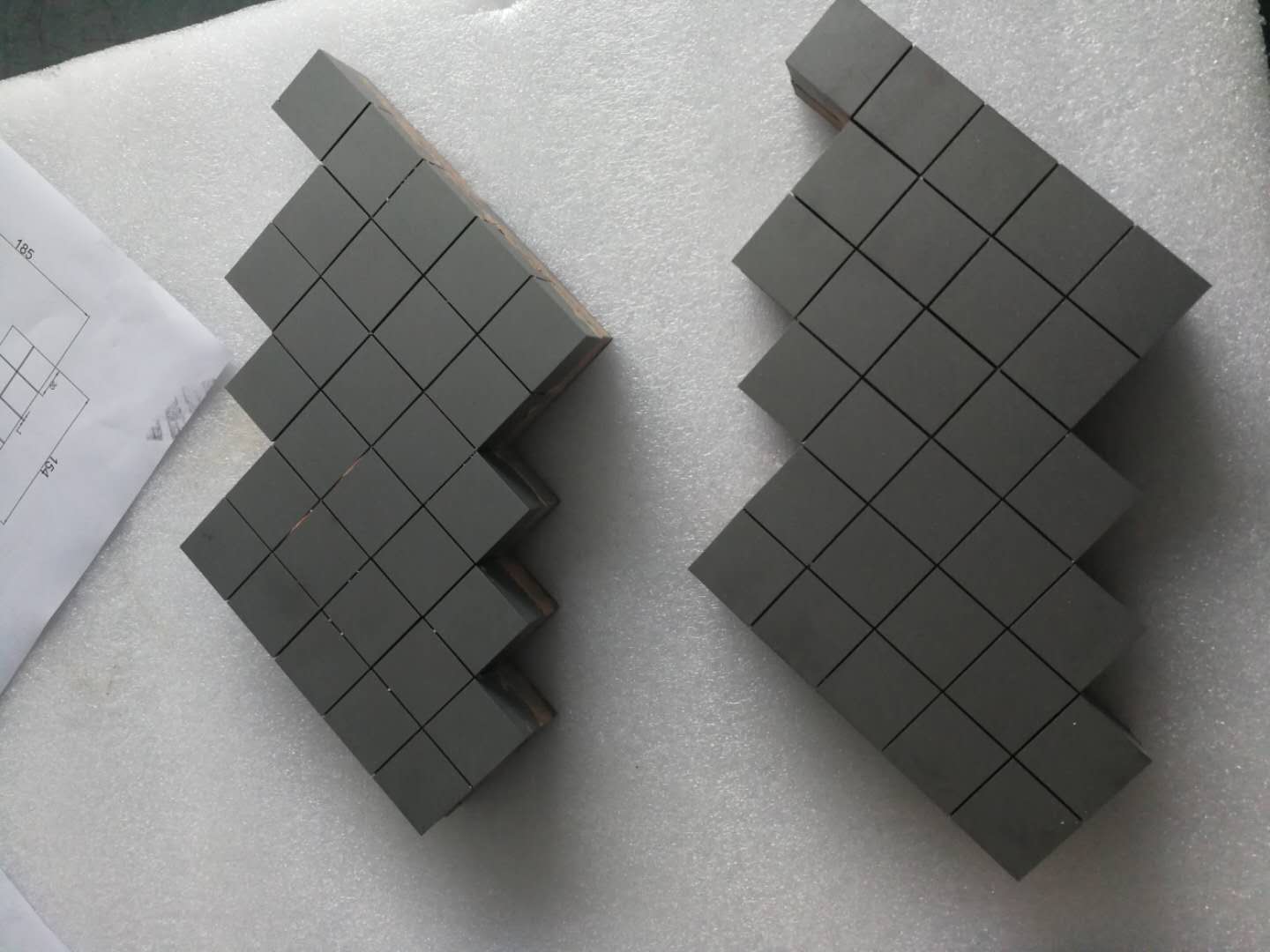

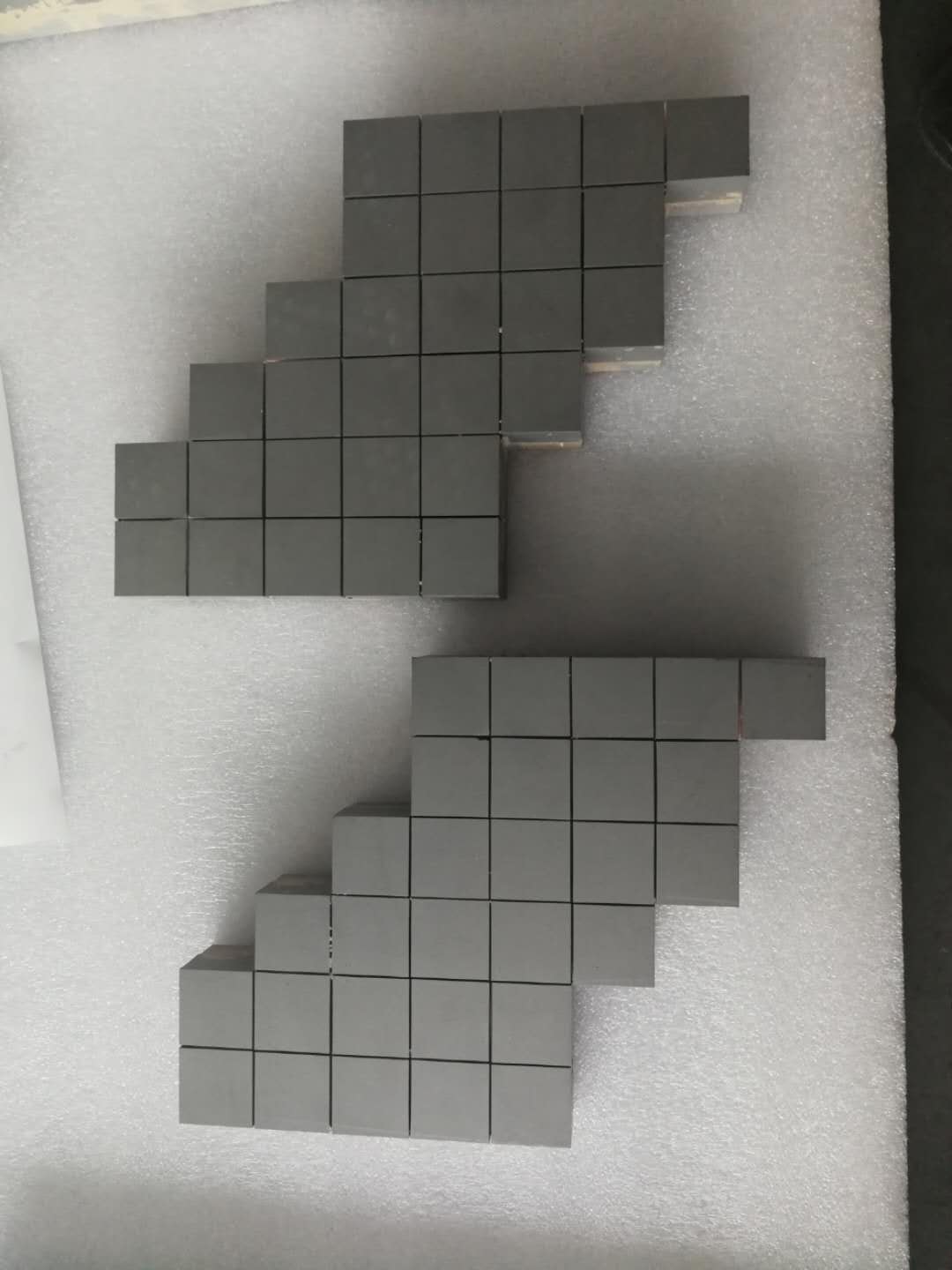

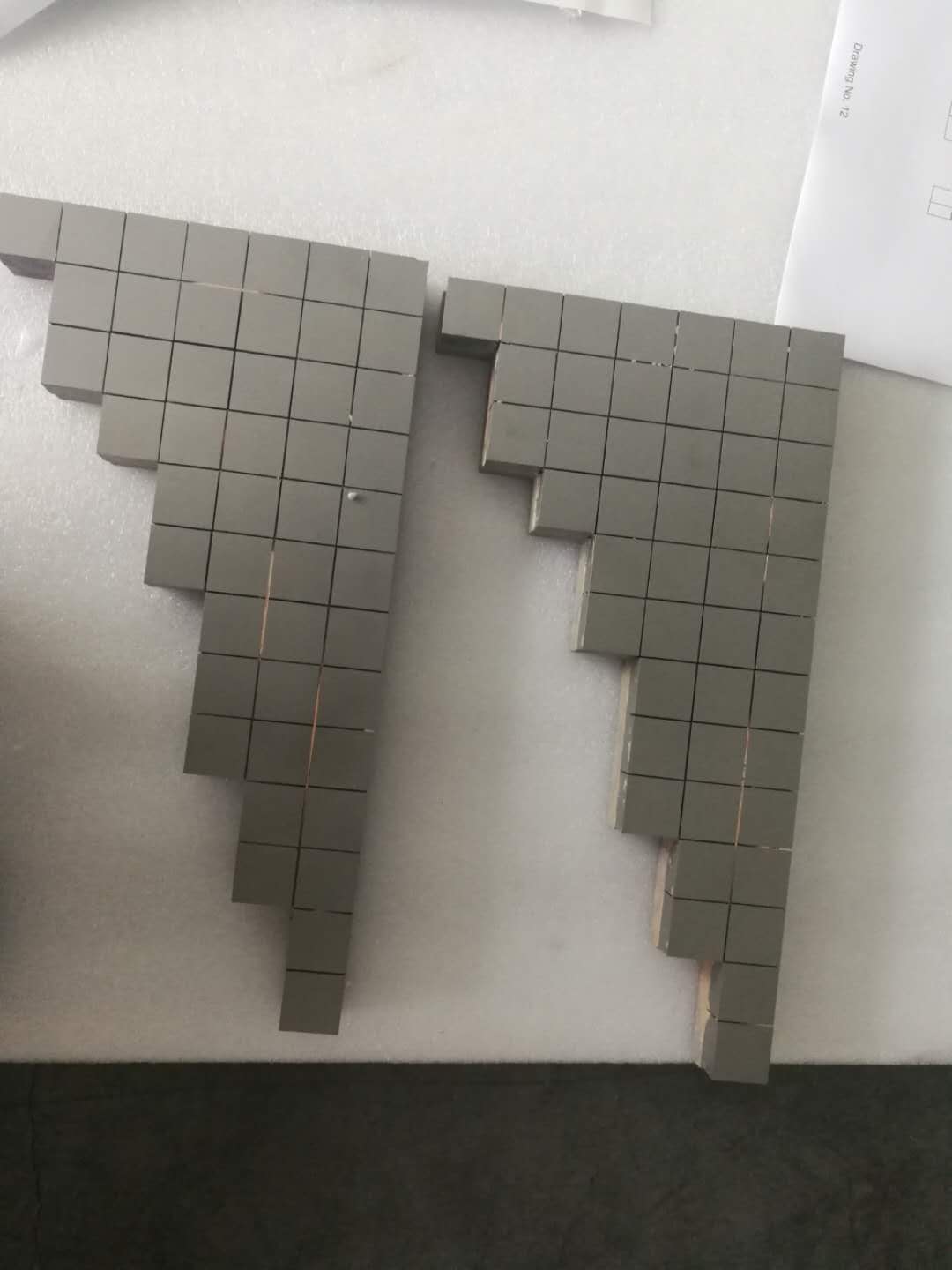

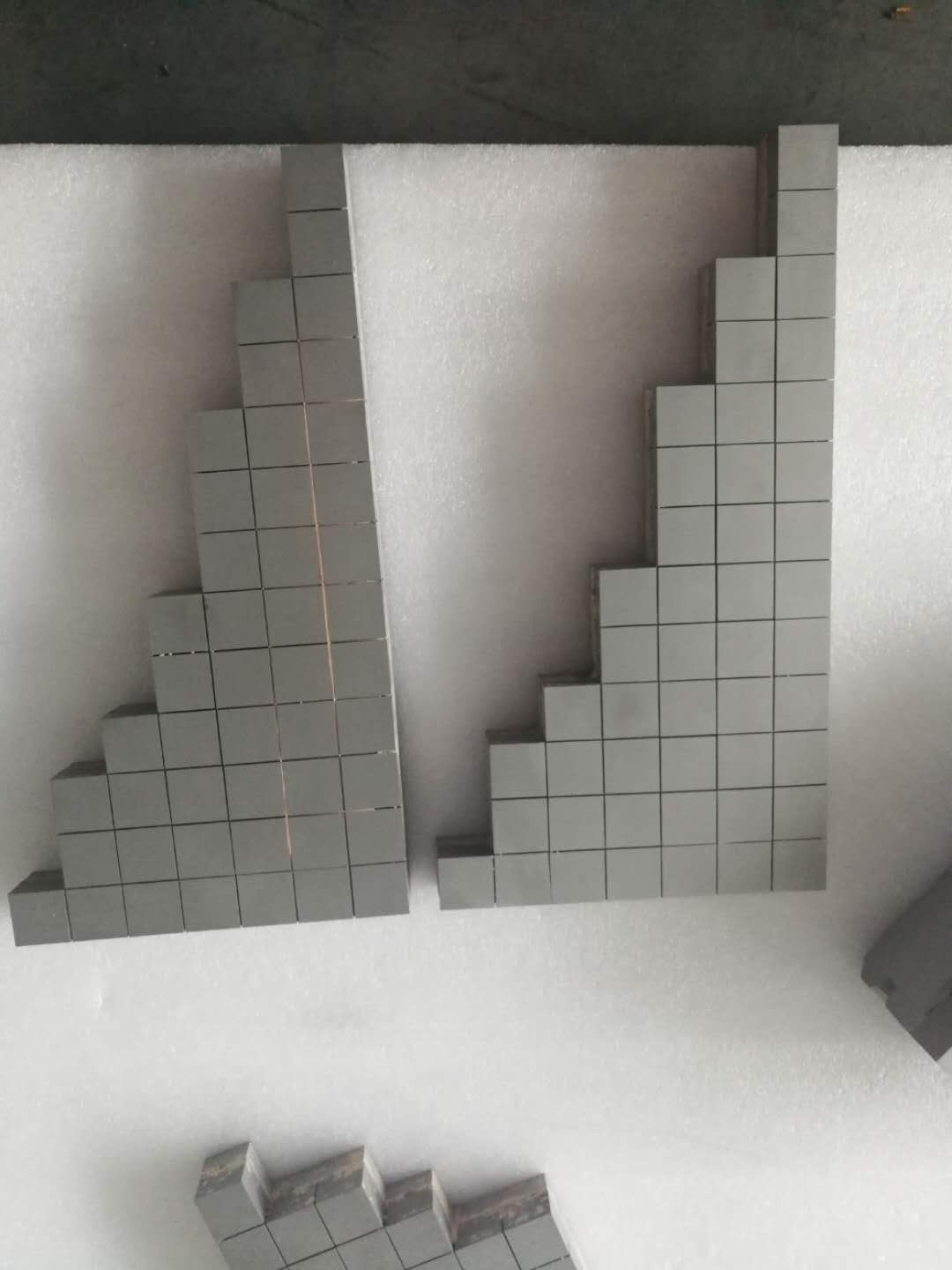

Application: transfer chute hopper

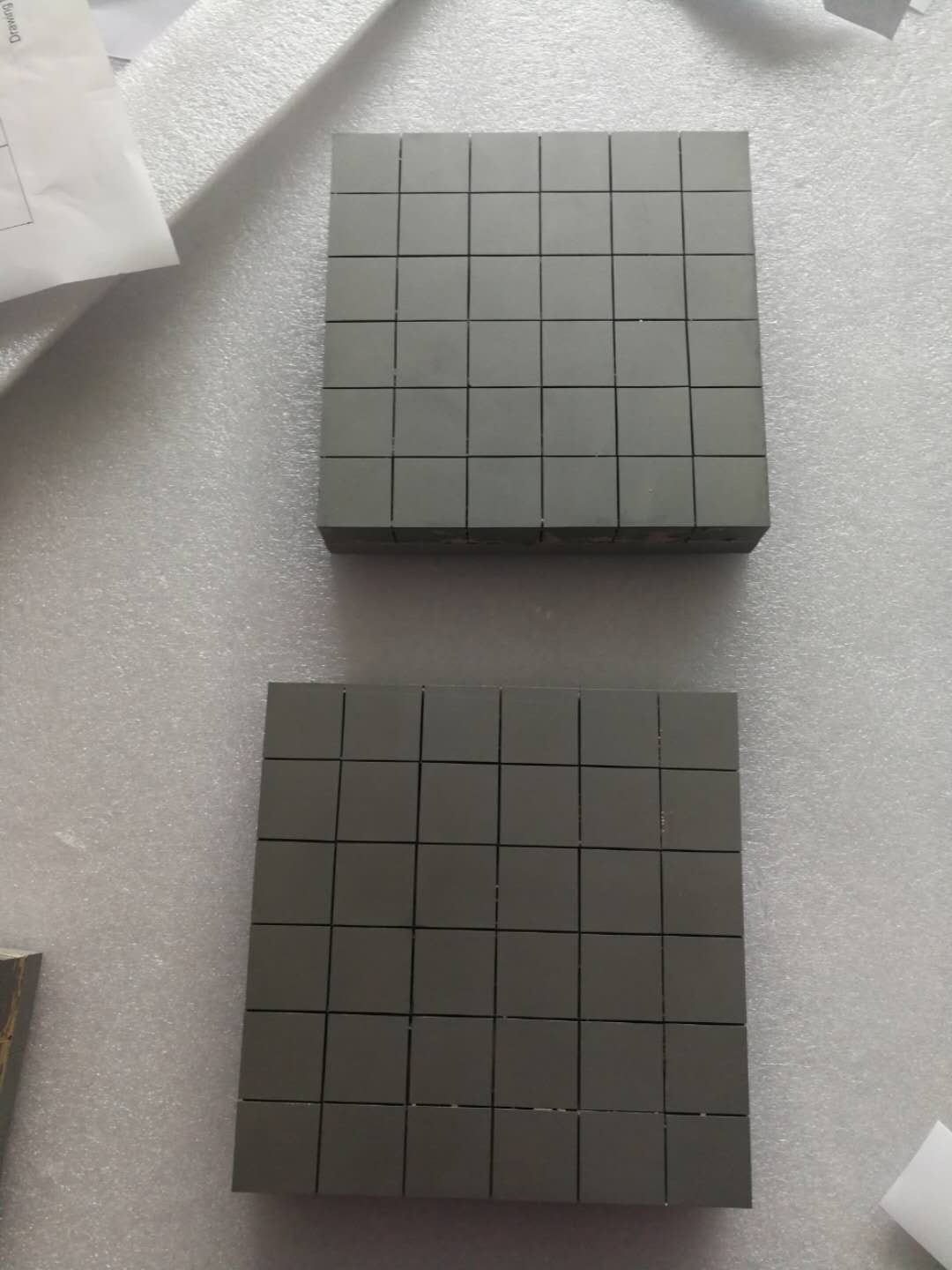

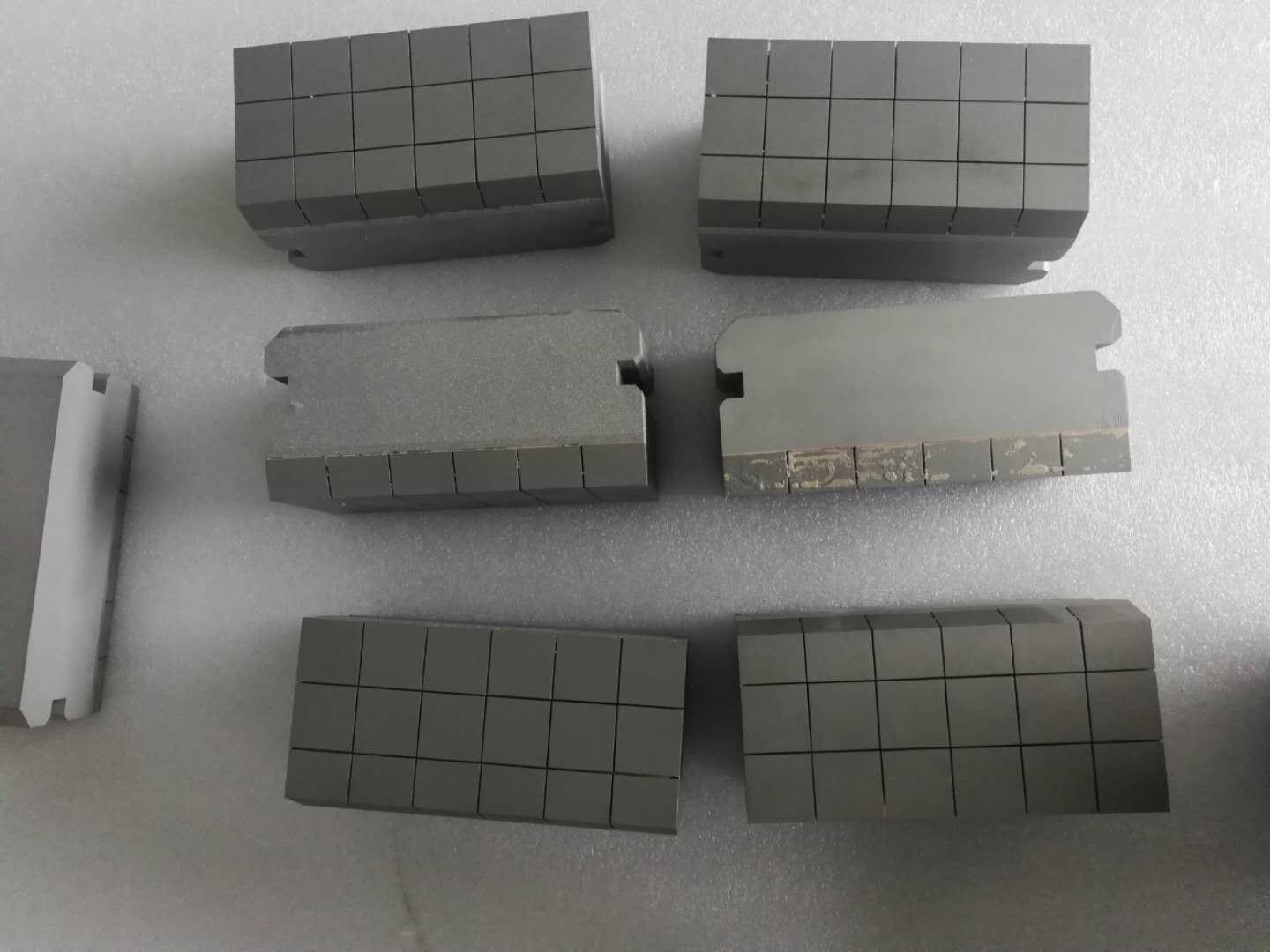

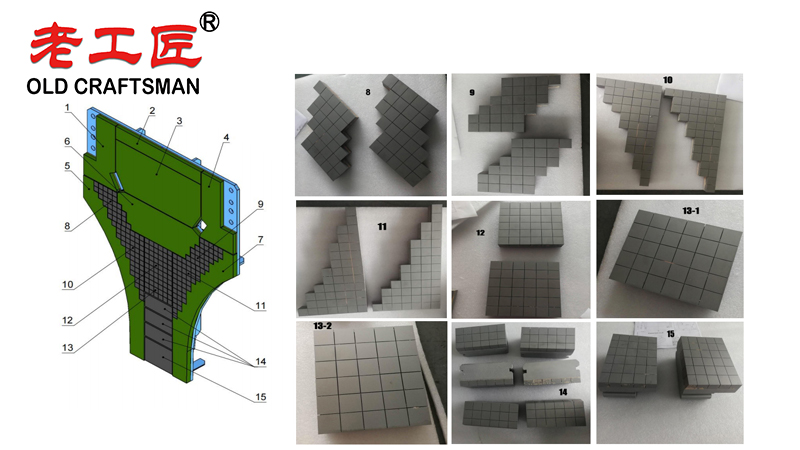

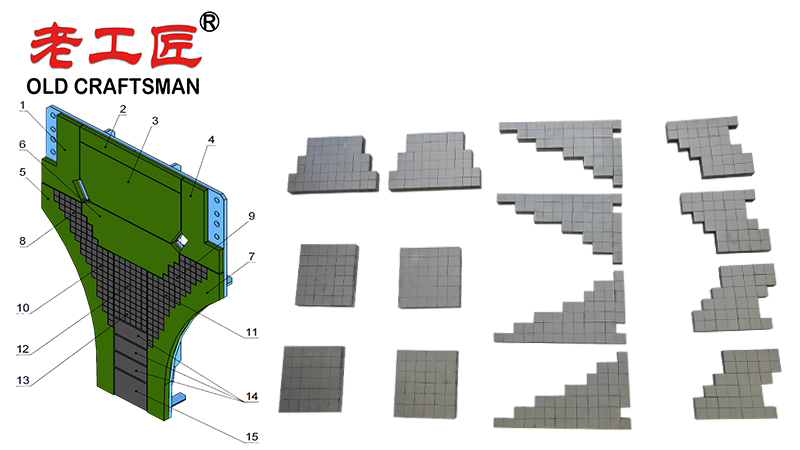

Project detail: its carbide brazed wear plates used in transfer chute hopper

Material used: 18mm thickness 30mm*30mm carbide tiles vacuum brazed on the steel plates, different shapes.

In the brutally abrasive world of mining, equipment longevity is directly tied to operational efficiency and cost. Every hour of unplanned downtime for crushers, hoppers, chutes, or conveyor systems translates to significant production losses. This is where tungsten carbide wear liners emerge as a critical technological solution, offering unparalleled protection for the industry’s most vulnerable components.

Tungsten carbide (WC), a composite material of hard tungsten carbide particles bonded in a tough cobalt or nickel matrix, possesses exceptional properties ideal for mining applications. Its extreme hardness, typically between 8.5 and 9 on the Mohs scale (second only to diamond), provides superior resistance to abrasion from constant contact with hard, sharp aggregates like ore, granite, and gravel. Unlike conventional steel liners that wear down through material loss, tungsten carbide liners are engineered to maintain their protective profile for dramatically longer periods.

These liners are not monolithic plates but are most commonly applied as embedded tiles or cast-in inserts within a steel backing plate. This design creates a durable, composite armor. As the softer steel backing wears slightly, the protruding tungsten carbide buttons or strips become the primary contact point, absorbing the abrasive impact. This configuration ensures that even under extreme stress, the liner system remains intact and functional long after a steel-only liner would have failed.

The benefits for mining operations are substantial. First and foremost is the dramatic extension of service life—tungsten carbide liners can last 6 to 10 times longer than high-chrome steel or manganese steel alternatives. This drastically reduces the frequency of liner replacements, minimizing costly downtime, labor expenses, and inventory needs for spare parts. Furthermore, the consistent protection maintains the original geometry of the protected component (like a feed chute), ensuring optimal material flow and preventing bottlenecks caused by material build-up on worn, uneven surfaces.

Applications are widespread across the mining circuit. They are indispensable in primary crusher feed plates, slurry pump casings, classifier wear shoes, dump truck beds, screen decks, and anywhere high-velocity, high-impact abrasion occurs. By shielding the base machinery, they also reduce maintenance on the core equipment itself.

Carbide Wear Liners and stainless steel panty liners are engineered for demanding applications requiring exceptional corrosion resistance and a wide range of mechanical properties. While high-carbon and carbon steels offer excellent hardness and wear performance, stainless steels provide superior resistance to rust and oxidation in harsh environments. Please contact us for tailored solutions to meet your specific needs.

In conclusion, tungsten carbide wear liners represent a prime example of a strategic investment in mining operations. While the initial cost is higher than traditional materials, the profound reduction in total lifecycle costs, coupled with enhanced operational reliability and throughput, makes them an essential component for any operation focused on maximizing productivity and minimizing abrasive wear. They are the hardened shield that allows the relentless work of mining to continue with minimal interruption.

Belt scraper Brazing brazingprocess CARBDIE HAMMER carbide Carbide belt scraper carbidebrazing carbide hammer Crusher CRUSHER HAMMER Informational Internal stress metal mining Refractory Brick Mold Secondary belt cleaner scraper stresses VSI crusher wear plates welding